News

OCA vs. OCR: Choosing the Optimal Lamination Solution for High-Performance Touchscreen

OCA vs. OCR: Choosing the Optimal Lamination Solution for High-Performance touchscreen

OCA vs. OCR: Choosing the Optimal Lamination Solution for High-Performance touchscreen

Why Lamination Technology Matters

In modern devices such as smartphones, tablets, automotive displays, medical equipment, and industrial control panels, a high-quality touchscreen is defined by more than just responsive touch performance.

Optical clarity, structural integrity, and long-term reliability are equally critical.

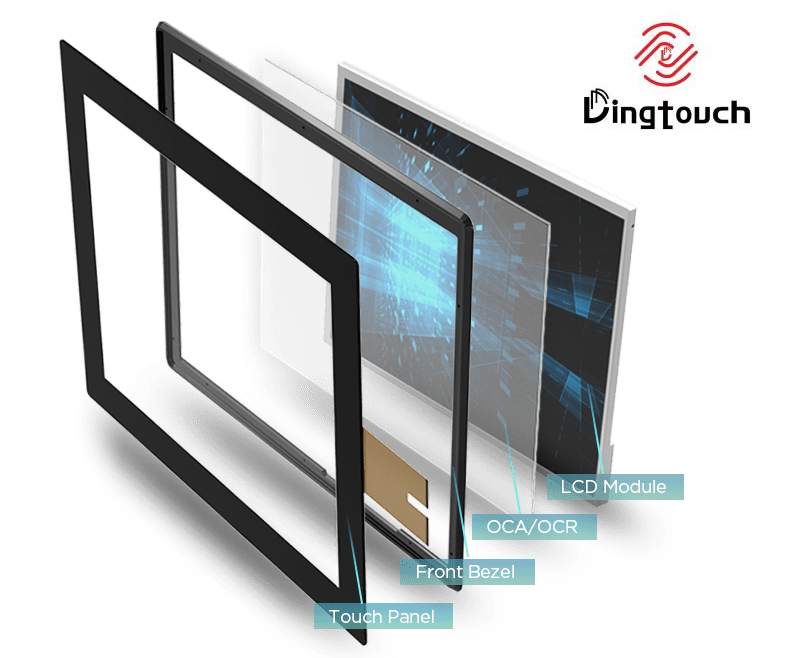

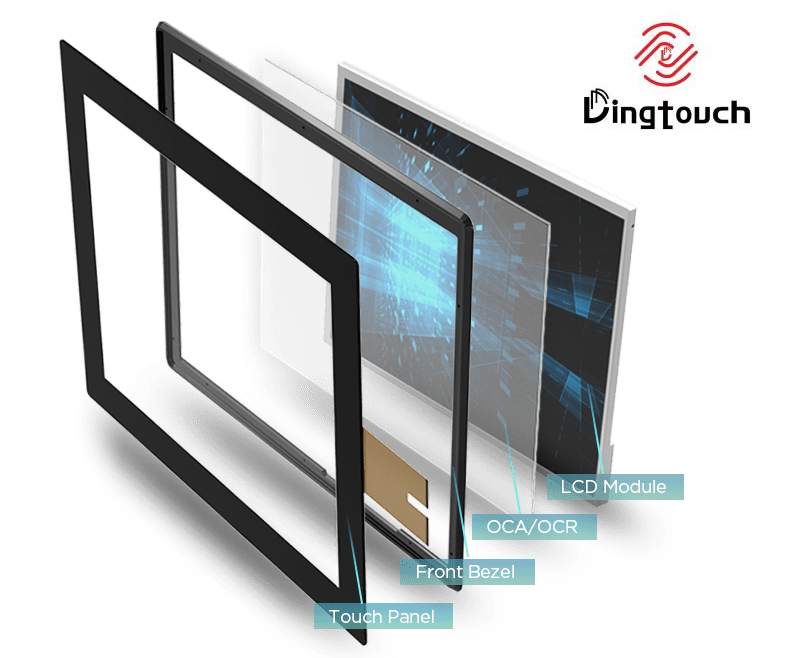

At the core of these attributes lies lamination technology—specifically, the adhesive layer that bonds the touch sensor, cover glass, and display module.

An inappropriate lamination method can lead to:

-

Reduced display transparency

-

Touch inaccuracies

-

Delamination over time

-

Moisture or dust intrusion

In this article, we compare two industry-leading lamination solutions:

OCA (Optically Clear Adhesive) and OCR (Optically Clear Resin)—explaining how they work, their strengths and limitations, and how to choose the right solution for your touchscreen project.

OCA (Optically Clear Adhesive): Precision for Flat Display

OCA is a solid, film-type optical adhesive widely used in capacitive touch panels and LCD/OLED bonding.

It is applied using vacuum lamination equipment, ensuring accurate alignment, uniform pressure, and effective bubble elimination.

Key Advantages of OCA

Exceptional Optical Performance

-

Light transmittance exceeding 99%

-

Extremely low haze for a seamless, “one-glass” visual effect

Mature and Stable Manufacturing Process

-

Excellent thickness uniformity

-

High production yield and process consistency

Clean and Controlled Lamination

-

No liquid flow

-

Reduced risk of edge contamination or equipment fouling

Limitations of OCA

Higher Overall Cost

-

Premium adhesive materials

-

Capital-intensive lamination equipment

Limited Flexibility

-

Not ideal for curved, 2.5D/3D, or irregular surfaces

-

Increased risk of bubbles on very large displays

Low Reworkability

-

Once bonded, removal is extremely difficult without damaging components

OCR (Optically Clear Resin): Flexible Bonding for Complex Designs

OCR is a liquid optical adhesive applied by dispensing or coating, then cured using UV light or thermal processes to form a transparent bonding layer.

Key Advantages of OCR

Excellent Structural Adaptability

-

Ideal for curved glass, flexible OLED, and irregular shapes

-

Well-suited for automotive interiors and modern industrial designs

Cost-Effective for Large-Format Display

-

Lower material and equipment costs

-

Commonly used in automotive displays, digital signage, and large HMIs

Superior Gap-Filling Capability

-

Liquid resin compensates for surface unevenness

-

Reduces internal stress and improves mechanical stability

Potential for Rework

-

In some cases, bonding can be reversed using controlled heat and tools

Limitations of OCR

Process Complexity

-

Requires precise control of dispensing volume, curing time, and UV exposure

Risk of Flow and Contamination

-

Improper sealing may cause resin overflow into IC or FPC areas

Long-Term Optical Stability Concerns

-

Higher susceptibility to bubbles, impurities, or yellowing compared to OCA

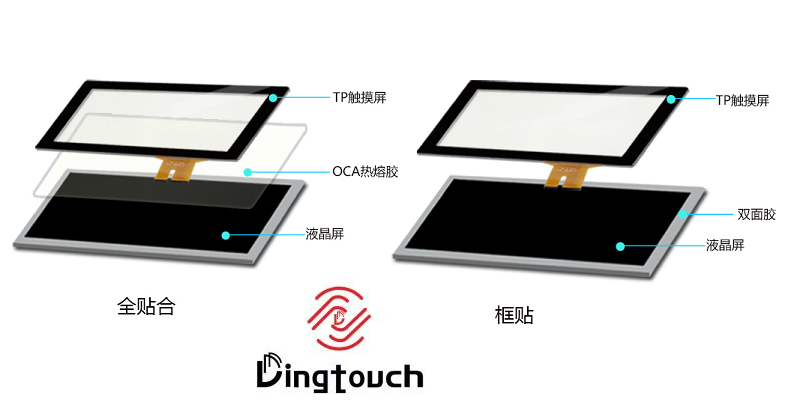

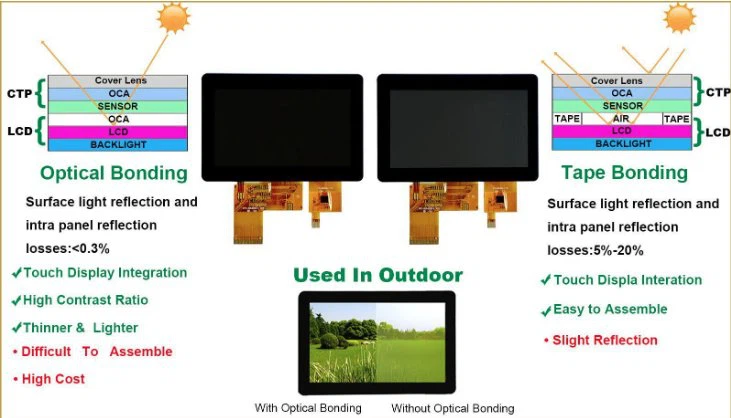

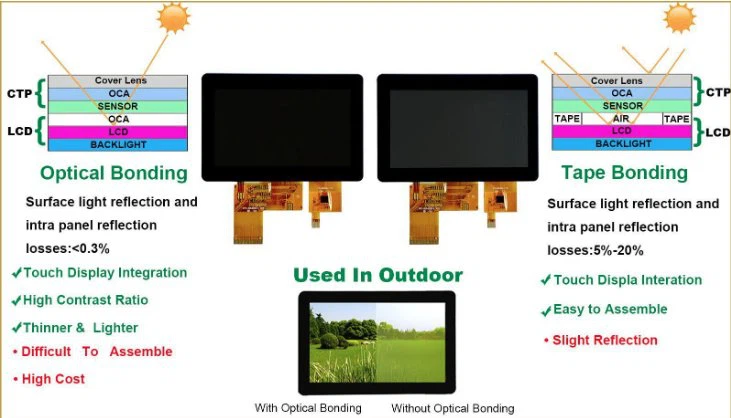

Full Lamination vs. Air Gap: Understanding the Structural Difference

1. Air Gap (Frame Lamination)

Air Gap lamination bonds the touch panel only around the edges using double-sided tape, leaving an air layer between the cover glass and the sensor.

Impact on Display Quality

-

Increased light reflection and refraction

-

Washed-out or grayish appearance

-

Noticeable “floating” effect under strong lighting

Impact on Touch Performance

-

Reduced signal-to-noise ratio (SNR)

-

Lower sensitivity due to increased finger-to-sensor distance

-

Potential Newton’s Rings or ripple effects under pressure

2. Full Lamination (Using OCA or OCR)

Full lamination completely fills the internal gap using OCA or OCR, eliminating trapped air between layers.

Impact on Display Quality

-

Refractive index matching minimizes reflection

-

Higher contrast, richer colors, and improved brightness

-

Significantly enhanced sunlight readability—a hallmark of premium displays

Impact on Touch Performance

-

Increased capacitance change (ΔC)

-

Faster response and higher touch accuracy

-

Improved mechanical strength and resistance to deformation

-

Better sealing against dust and moisture

How to Choose the Right Lamination Solution

Every touchscreen project has unique technical and commercial requirements.

Choose OCA if your application requires:

-

Flat glass structures

-

Premium optical clarity

-

High-volume, stable mass production

Choose OCR if your design involves:

-

Curved or flexible displays

-

Large-format screens

-

Cost-sensitive or structurally complex applications

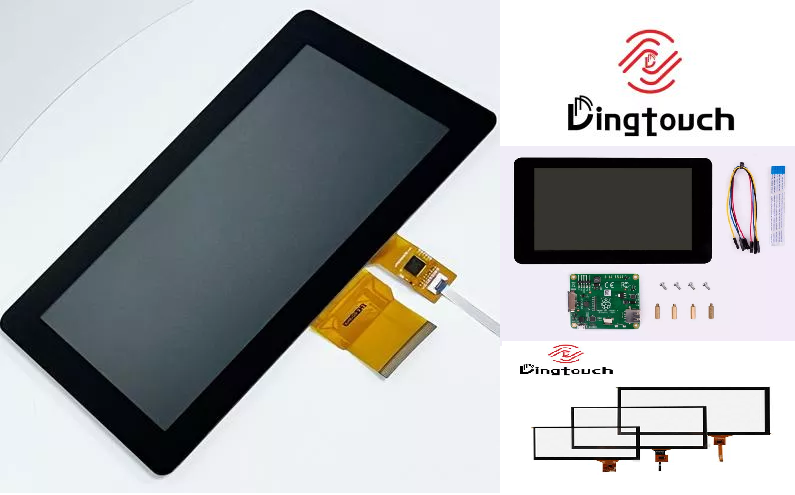

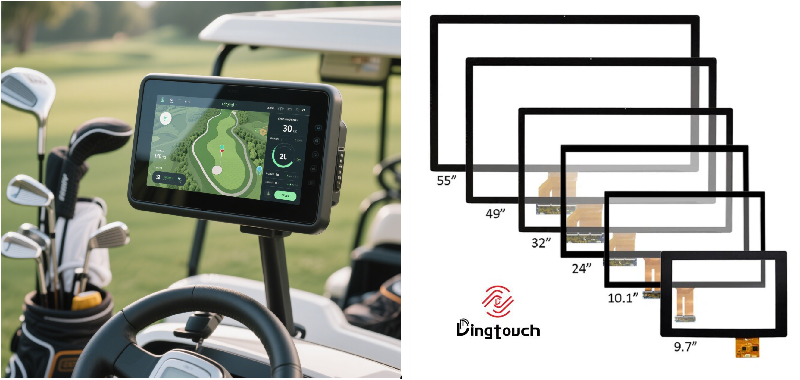

Customized Lamination Solutions by DINGTouch

At DINGTouch, we provide customized OCA and OCR lamination solutions tailored to your display size, structure, and application environment.

Our engineering team ensures the optimal balance between:

-

Optical performance

-

Touch accuracy

-

Mechanical reliability

-

Long-term durability

![]() Not sure which technology fits your project?

Not sure which technology fits your project?

Contact Saela@szdingtouch.com — our experts are ready to help you define the best lamination strategy for your touchscreen design.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch