News

Advantages and Disadvantages of Lamination Methods in TFT LCD Capacitive Touch Screen

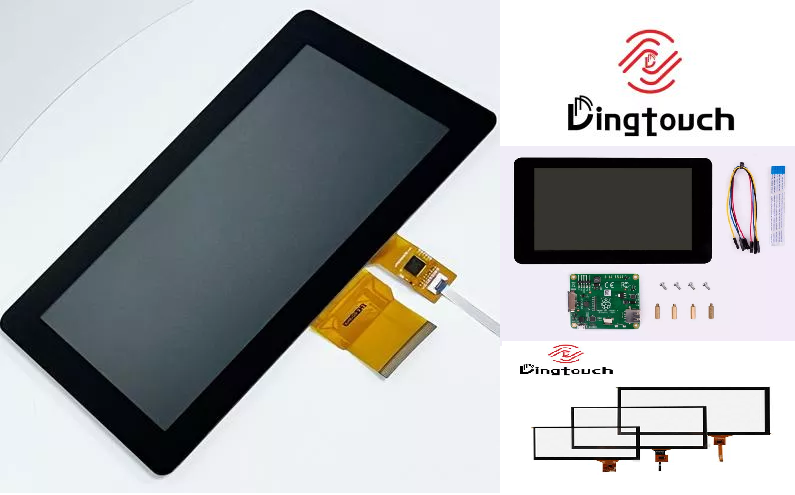

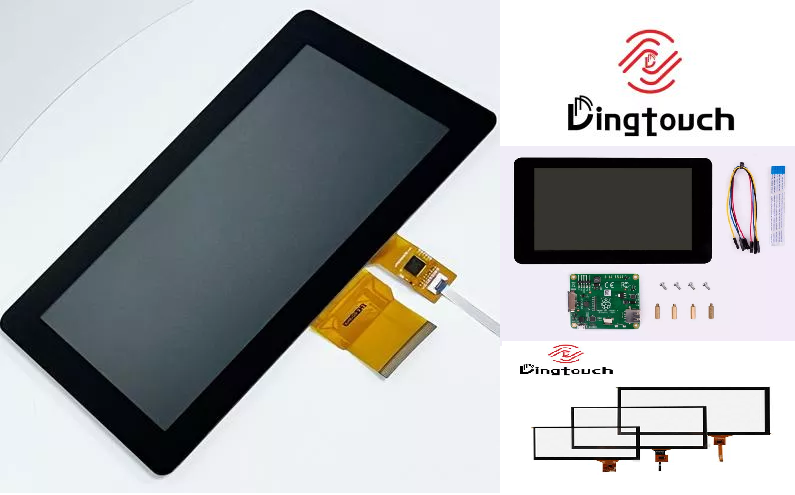

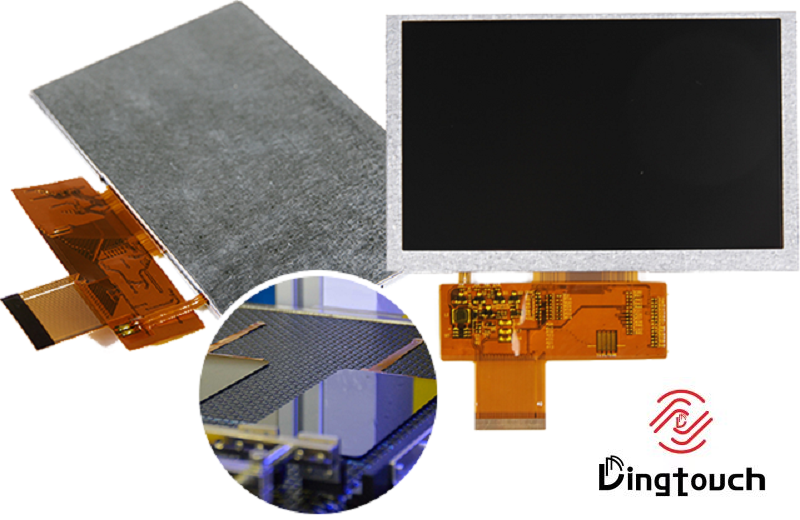

A Professional Insight from DINGTouch Touch Display Solutions

Thin-Film Transistor Liquid Crystal Display (TFT LCD) combined with capacitive touch screens have become the standard interface for modern interactive devices—ranging from smartphones and tablets to industrial HMI panels, medical equipment, and commercial displays.

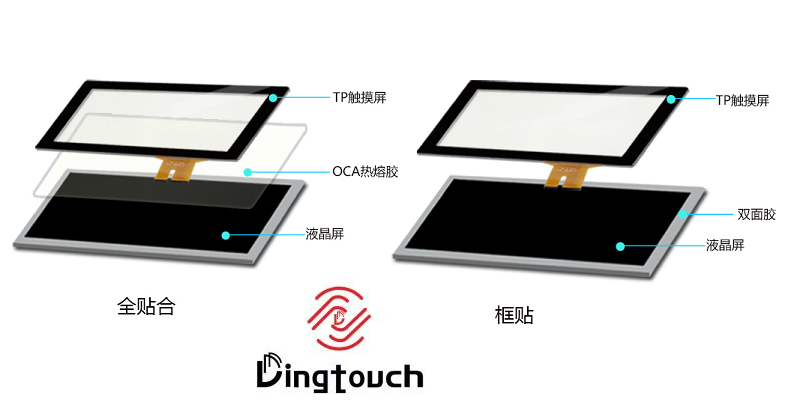

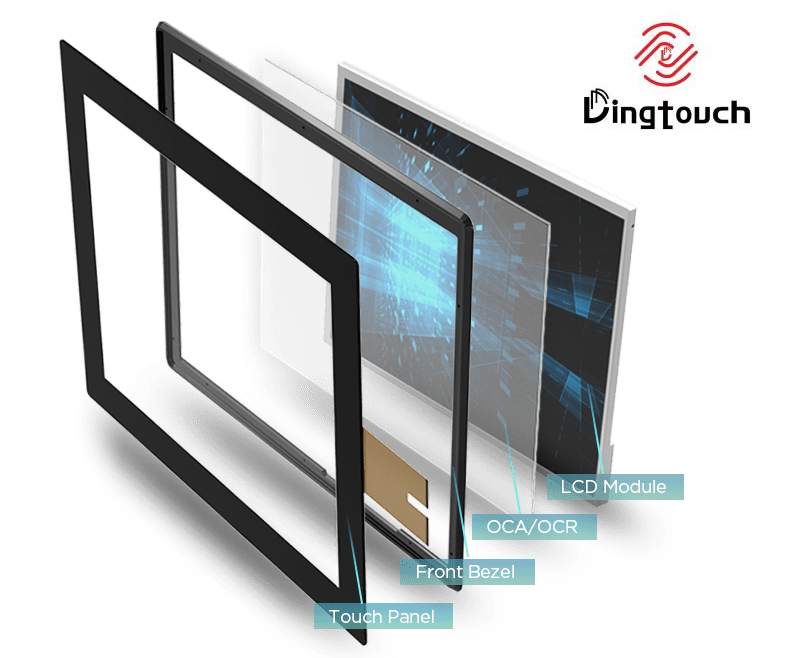

At the heart of these advanced displays lies a critical manufacturing process: lamination. By bonding the cover glass, capacitive touch sensor, and LCD panel using Optically Clear Adhesive (OCA) or Optically Clear Resin (OCR), lamination directly determines optical performance, touch accuracy, durability, and long-term reliability.

With over 10 years of experience in custom touch screen manufacturing, DINGTouch provides professional lamination solutions tailored to consumer, industrial, and medical-grade TFT LCD display. In this article, we explore the key advantages and disadvantages of lamination methods, helping you make informed decisions for your display projects.

Why Lamination Technology Matters in TFT LCD Touch Display

Unlike traditional air-gap assembly, lamination creates a fully bonded structure that enhances both visual and tactile performance. However, achieving consistent quality requires advanced materials, cleanroom environments, and precise process control—areas where DINGTouch excels.

Advantages of the Lamination Method

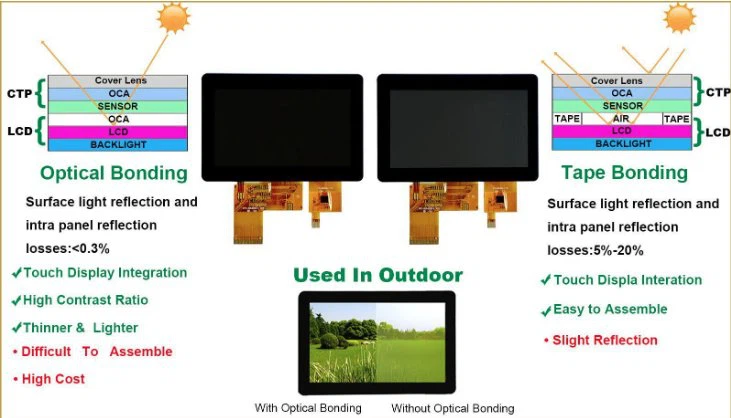

1. Superior Optical Clarity and Display Performance

Lamination eliminates air gaps between layers, significantly reducing internal light refraction and reflection.

Key benefits include:

-

Higher brightness and contrast

-

Improved sunlight readability

-

Wider viewing angles with reduced glare

-

Clearer image quality for IPS and high-resolution TFT LCD panels

This makes laminated displays ideal for outdoor devices, medical monitors, and high-end consumer electronics.

2. Enhanced Durability and Impact Resistance

The adhesive layer acts as a shock-absorbing buffer, helping protect the display against external impact.

Performance advantages:

-

Reduced risk of glass cracking from drops or vibration

-

Improved resistance to dust and moisture intrusion

-

Longer product lifespan in harsh industrial environments

DINGTouch laminated solutions are widely used in industrial control systems, automotive displays, and rugged terminals.

3. Improved Touch Sensitivity and Accuracy

By minimizing the distance between the touch sensor and the LCD panel, lamination greatly enhances touch responsiveness.

Touch performance improvements:

-

Faster and more consistent touch response

-

Reduced parallax error

-

Higher precision for multi-touch gestures

This is critical for medical devices, smart education systems, and precision control applications.

4. Thinner, Lighter, and More Modern Design

Lamination removes bulky air gaps, enabling slimmer and lighter display modules.

Design advantages:

-

Reduced overall module thickness

-

Lighter device weight

-

Sleek, modern industrial design

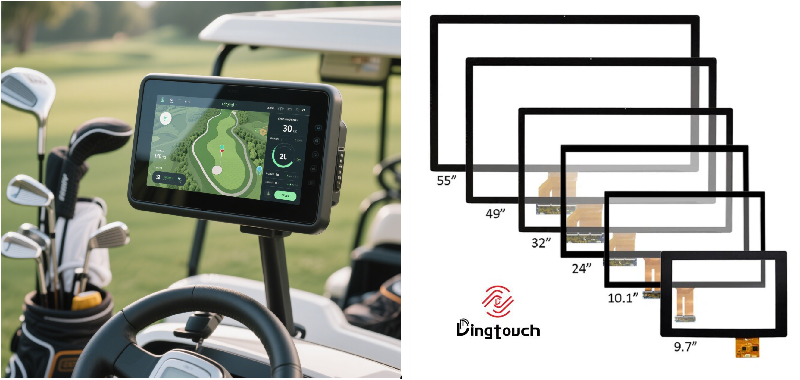

DINGTouch supports ultra-thin laminated touch displays across sizes from 2.8″ to 65″, meeting both aesthetic and functional demands.

5. Higher Manufacturing Yield and Consistency

Advanced vacuum lamination technology significantly improves production stability.

Manufacturing benefits:

-

Fewer defects such as bubbles or misalignment

-

Better consistency across mass production

-

Lower long-term cost through reduced rework

DINGTouch automated lamination lines ensure high yield rates and stable quality for large-scale OEM and ODM projects.

Disadvantages of the Lamination Method

1. Higher Manufacturing Complexity and Cost

Lamination requires:

-

Cleanroom production environments

-

Precision vacuum lamination equipment

-

Skilled process control

Additionally, OCA and OCR materials are more expensive than traditional assembly solutions, increasing upfront manufacturing costs.

2. Risk of Delamination or Bubble Formation

If process control is inadequate, lamination defects may occur.

Potential risks include:

-

Air bubbles affecting display appearance

-

Delamination under extreme temperature or humidity

-

Optical degradation over time

This highlights the importance of choosing an experienced lamination partner like DINGTouch.

3. Limited Repairability

Once laminated, display layers are permanently bonded.

Implications:

-

Difficult or impossible to separate layers for repair

-

Damage to one layer may require full module replacement

This can increase after-sales maintenance costs.

4. Reduced Design Flexibility After Lamination

Post-lamination modifications are extremely limited.

Design constraints:

-

Touch or LCD changes require process redesign

-

Additional layers cannot be easily added later

Early-stage design validation is critical for laminated displays.

5. Potential Optical or Alignment Issues

Uneven adhesive distribution or misalignment may lead to:

-

Brightness or color uniformity issues

-

Touch position inaccuracies

DINGTouch mitigates these risks through strict process standards and optical inspection systems.

OCA vs. OCR: Choosing the Right Lamination Solution

-

OCA Lamination: Ideal for thin, high-resolution displays with flat surfaces and mass production needs.

-

OCR Lamination: Better suited for curved glass, irregular surfaces, or thicker modules requiring gap filling.

DINGTouch provides custom OCA and OCR lamination solutions based on application requirements, environmental conditions, and cost targets.

Conclusion: Is Lamination the Right Choice for Your TFT LCD Touch Screen?

The lamination method delivers exceptional optical clarity, touch precision, durability, and modern design, making it the preferred solution for high-performance TFT LCD capacitive touch screens.

While it introduces higher manufacturing costs and repair complexity, these challenges are outweighed by the performance benefits—especially when partnered with an experienced manufacturer.

With continuous innovation in materials and processes, laminated TFT LCD display are becoming more reliable, cost-efficient, and visually superior.

![]() DINGTouch specializes in custom laminated touch display solutions for industrial, medical, automotive, and commercial applications—helping you achieve the perfect balance between performance, reliability, and cost.

DINGTouch specializes in custom laminated touch display solutions for industrial, medical, automotive, and commercial applications—helping you achieve the perfect balance between performance, reliability, and cost.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch