News

Introduction to Optical Bonding Lamination: OCA and OCR

Introduction to Optical Bonding Lamination: OCA and OCR

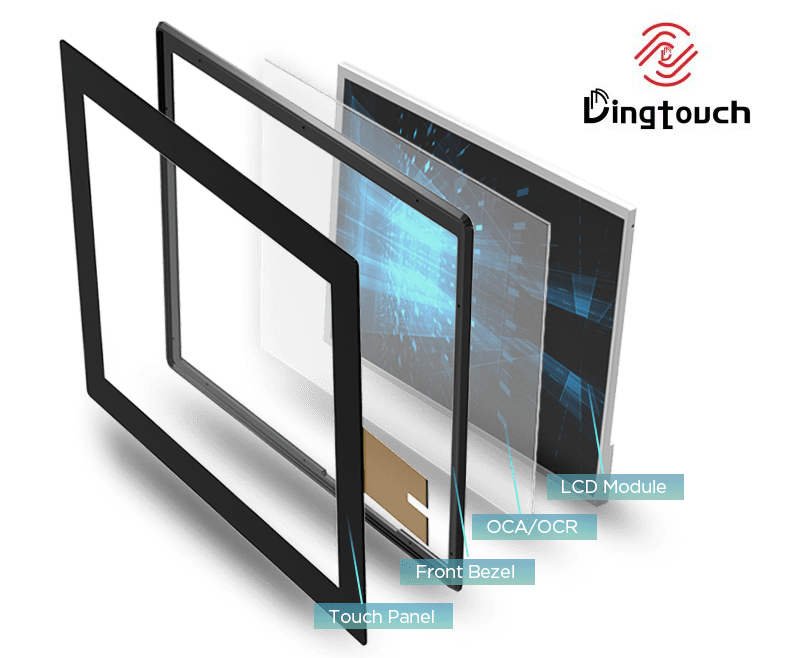

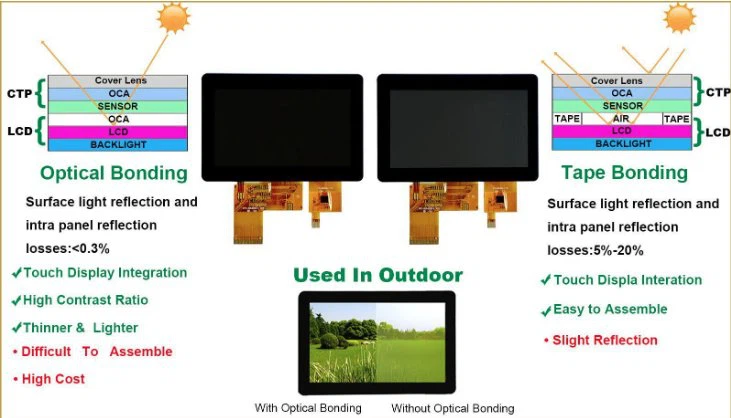

Optical bonding lamination is a display enhancement technology that directly bonds a touch screen to the underlying display module. By eliminating the air gap between layers, this technique significantly improves visual clarity, durability, and readability, especially under challenging environmental conditions.

This guide introduces the two primary optical bonding methods—OCA (Optically Clear Adhesive) and OCR (Optical Clear Resin/LOCA)—highlighting their materials, features, limitations, and use cases.

What is Optical Bonding?

Optical bonding involves filling the space between the touchscreen and display with a transparent adhesive. This is done using pressure, heat, or UV curing to ensure full surface contact without air pockets or moisture. By eliminating internal reflections and refractions, optical bonding boosts:

-

Display contrast

-

Brightness and sharpness

-

Sunlight readability

-

Dust, water, and impact resistance

It also enhances structural strength and protects the screen in rugged environments.

1. OCA Lamination (Double-Sided Adhesive Bonding)

Material:

OCA is a solid optically clear adhesive film with double-sided stickiness and excellent transparency. It is commonly used in small to medium-sized touch display assemblies.

Key Features:

-

✅ High Transparency: Transmittance >90%, preserving display clarity and brightness.

-

✅ Strong Adhesion: Reliable bond between display and touch panel.

-

✅ Anti-Glare & Energy Saving: Reduces reflection, increases LCD brightness and contrast, especially under sunlight.

Limitations:

-

❌ Surface Stickiness: Attracts dust, and bubbles may form when peeling off release film.

-

❌ Manual Lamination Issues: Uneven pressure can cause wrinkles and air bubbles.

-

❌ Low Fluidity: Not ideal for surfaces with grooves or ink/ITO lines.

-

❌ Size Limitation: Difficult to use for large displays; lower efficiency and higher labor cost.

2. OCR / LOCA Lamination (Liquid Optical Clear Adhesive)

Material:

OCR (also known as LOCA) is a liquid transparent adhesive with high flowability, used in full lamination processes, especially for irregular or framed display.

Key Features:

-

✅ Ultra-High Transparency: Light transmittance >98%; resistant to yellowing.

-

✅ Excellent Flowability: Fills micro-gaps and uneven surfaces, ensuring flat bonding.

-

✅ Flexible Curing: Can be UV or heat cured depending on formulation.

Limitations:

-

❌ Edge & FPC Curing Challenge: Border areas may not cure completely, requiring side UV illumination.

-

❌ Overflow Risk: Demands precise control of glue volume and pattern.

-

❌ Air Bubbles: Can form during dispensing or covering steps.

-

❌ Thickness Inconsistency: Leveling process may result in uneven glue layers.

-

❌ Movement Risk During Curing: Can cause misalignment, especially with large panels.

Comparison: OCA vs. OCR

| Feature | OCA (Double-Sided Adhesive) | OCR / LOCA (Liquid Adhesive) |

|---|---|---|

| Process Simplicity | Simple, manual or semi-auto | Complex, requires precision equipment |

| Cost | Lower cost, suitable for mass production | Higher cost, higher lamination quality |

| Visual Quality | Good, may have minor visual defects | Excellent clarity, seamless finish |

| Bubble Risk | Higher, especially with dust | Moderate, depends on process control |

| Size Suitability | Ideal for small/medium displays | Suitable for large/irregular displays |

| Application | General consumer products | High-end, industrial, automotive, rugged applications |

Conclusion

Optical bonding with OCA or OCR significantly enhances the user experience by delivering better visual performance, environmental resistance, and structural reliability.

-

Choose OCA for cost-effective, smaller-size products where high-end visual performance is not critical.

-

Choose OCR / LOCA for advanced applications requiring perfect clarity, durability, and lamination over complex surfaces or large screens.

By selecting the right bonding technology, manufacturers can optimize display performance based on specific application requirements, production scale, and budget.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

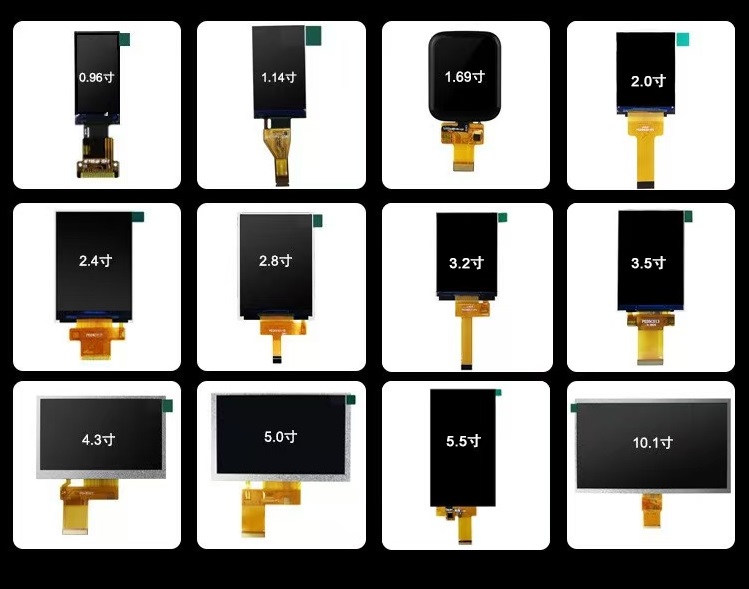

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medical touchscreen calibration, #capacitive touch calibration guide, #IEC 60601 touchscreen, #DINGTouch medical display, #touch screen accuracy, #touchscreen drift fix, #medical equipment touch solutions, #IP65 touch panel, #IK10 medical touchscreen, #glove touch medical monitor,#ILITEK Touch Controller IC Selection Guide

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch