News

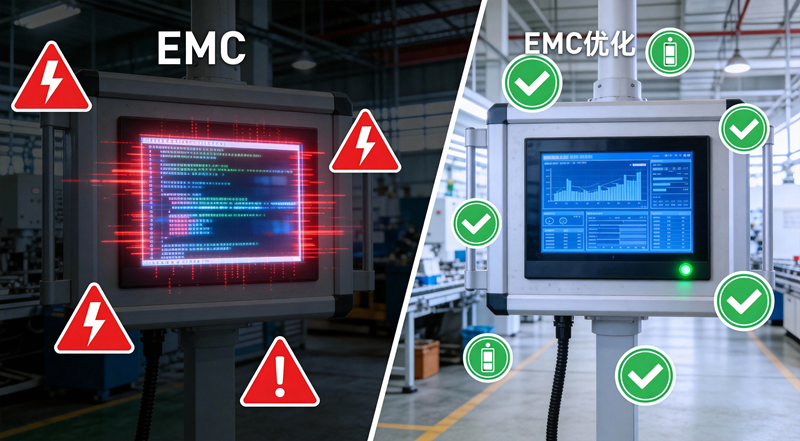

How EMC and EMI Requirements Shape Industrial LCD Display Design

How EMC and EMI Requirements Shape Industrial LCD Display Design

Understanding Signal Integrity, Shielding, Grounding, and Compliance Strategies in Industrial Display

In modern industrial environments, electronic systems operate amid intense electrical noise, high-power machinery, and densely packed signal networks. Under these conditions, industrial LCD display must do far more than present information clearly—they must remain electrically stable and coexist reliably with surrounding equipment.

This is why EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference) requirements play a decisive role in the design and integration of industrial LCD display.

This article explores how EMC and EMI influence industrial LCD design, clarifies their fundamental differences, and outlines practical, engineering-level strategies for achieving regulatory compliance and long-term reliability.

Key Insight: EMC compliance is achieved through disciplined system-level design—not isolated fixes.

Table of Contents

-

EMC vs. EMI: What’s the Real Difference?

-

Why Are Industrial LCD Displays Highly Sensitive to EMI?

-

How EMC Requirements Influence Industrial LCD Design Decisions

-

How EMC and EMI Compliance Are Verified in Practice

-

Conclusion: Designing EMC-Ready Industrial Display

EMC vs. EMI: What’s the Real Difference?

EMC vs. EMI: What’s the Real Difference?

Although often mentioned together, EMC and EMI describe different aspects of electromagnetic behavior.

-

EMI (Electromagnetic Interference) refers to unwanted electromagnetic emissions that can disrupt nearby electronic systems.

-

EMC (Electromagnetic Compatibility) describes a system’s ability to operate correctly within its electromagnetic environment—without causing interference or being affected by it.

In the context of industrial LCD display:

-

EMI focuses on what the display emits

-

EMC focuses on how the display behaves within the overall system

-

Both emission control and immunity performance must be addressed simultaneously

International compliance standards reflect this dual requirement, reinforcing a critical principle:

Key Insight: Controlling EMI alone is not enough—true compliance requires full EMC system integration.

Why Are Industrial LCD Display Highly Sensitive to EMI?

Industrial LCD display integrate multiple high-speed and high-energy subsystems, making them both sources and victims of electromagnetic interference.

Common EMI-sensitive elements include:

-

High-speed signal interfaces such as LVDS, eDP, and MIPI

-

Backlight driver circuits with high-frequency switching

-

Touch controller interfaces and sensor lines

-

Long or unshielded cable connections

In electrically noisy environments—such as factories, charging stations, or automation cabinets—these vulnerabilities become more pronounced. This directly links EMC design considerations to environmental reliability factors, as discussed in How Do Environmental Factors Impact Industrial LCD Reliability?

Key Insight: Industrial LCD displays are both EMI emitters and EMI receivers—EMC design must address both roles.

Designing display for electrically harsh environments? Explore DINGTouch industrial LCD solutions engineered with EMC-focused architectures.

How EMC Requirements Influence Industrial LCD Design Decisions

Meeting EMC requirements impacts nearly every stage of industrial LCD development—from schematic design to mechanical construction.

Key EMC-driven design considerations include:

-

Grounding and bonding strategies to establish stable reference planes

-

Controlled-impedance routing for high-speed signal integrity

-

Shielded cables, connectors, and harnesses to reduce emissions and susceptibility

-

Metal enclosures or conductive coatings for effective electromagnetic shielding

-

Optimized PCB layout to minimize loop areas and crosstalk

Crucially, these measures must be implemented early in the design phase. Attempting to “fix” EMC issues late in the development cycle often leads to increased cost, delayed certification, and compromised performance.

Key Insight: EMC compliance is designed in—not tested in.

How Are EMC and EMI Compliance Verified in Practice?

EMC and EMI performance are validated through standardized testing procedures defined by IEC, EN, and related international regulations. These tests evaluate both emissions and immunity under controlled, worst-case conditions.

Typical compliance tests include:

-

Radiated and conducted emissions testing

-

Electrostatic discharge (ESD) immunity

-

Electrical fast transient (EFT) immunity

-

Surge immunity and radiated RF immunity

These tests align closely with the broader regulatory framework discussed in What Are the Key IEC and EN Standards for Industrial LCD Displays?

Key Insight: EMC testing validates design assumptions under real-world stress conditions.

![]() Facing EMC challenges in your industrial display project? Contact the DINGTouch engineering team for EMC-focused LCD design support.

Facing EMC challenges in your industrial display project? Contact the DINGTouch engineering team for EMC-focused LCD design support.

Conclusion: Designing EMC-Ready Industrial LCD Display

EMC and EMI requirements fundamentally shape the design, integration, and validation of industrial LCD display. By addressing electromagnetic behavior at the system level, engineers can ensure stable operation, regulatory compliance, and long-term reliability in demanding industrial environments.

As a core article within the Compliance Cluster of the DINGTouch industrial LCD knowledge framework, this guide underscores the importance of EMC-aware design in modern industrial display systems—and highlights why EMC engineering is not optional, but essential.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

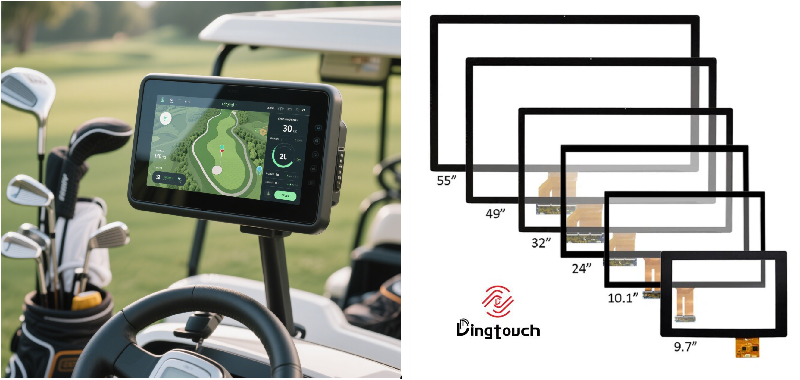

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch