News

LCD Display Brightness Too Low? A Complete Guide to Causes and Engineering Solutions for Low-Brightness LCD Screens

LCD Display Brightness Too Low?

A Complete Guide to Causes and Engineering Solutions for Low-Brightness LCD Screens

In industrial equipment, medical devices, outdoor terminals, and commercial display,

low LCD display brightness is one of the most common — and most underestimated — problems.

Insufficient brightness doesn’t just affect visual quality. It can lead to:

-

Poor readability under sunlight

-

Operational errors and safety risks

-

A low-end user experience that reduces product value

So the key questions are:

Why does an LCD screen appear too dim?

How can brightness be effectively improved at the engineering level?

This article provides a complete, practical explanation — from root causes to proven industry solutions.

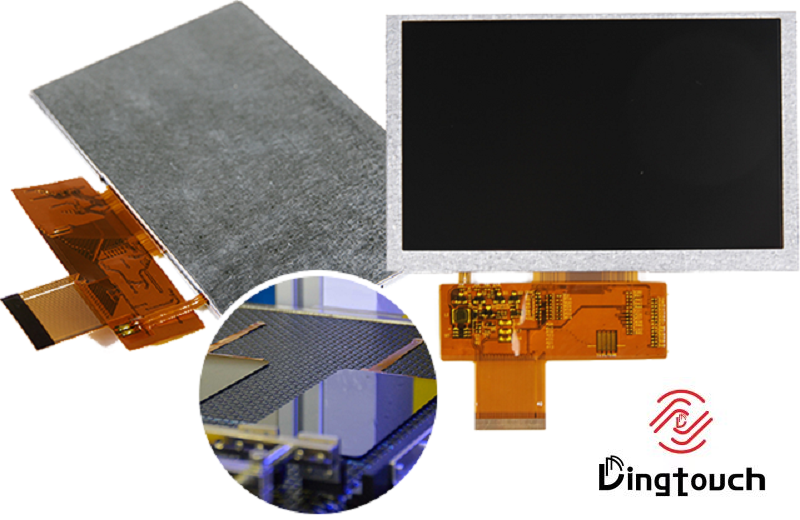

1. Common Causes of Low LCD Display Brightness

Low brightness is rarely caused by a single factor. In most cases, it results from multiple optical and structural limitations working together.

1. Backlight Brightness Is Too Low (Most Common Cause)

The backlight is the light source of an LCD display and defines the maximum brightness limit.

Typical brightness levels:

-

Standard indoor LCDs: 250–400 nits

-

Industrial / semi-outdoor displays: 600–800 nits

-

Outdoor high-brightness LCDs: 1000–2000+ nits

If an indoor-grade backlight is used in outdoor conditions, visibility issues are unavoidable.

2. Low Transmittance Polarizers

LCD panels use two polarizers (upper and lower).

If their light transmittance is low, overall brightness drops significantly.

-

Standard polarizers reduce more light

-

High-transmittance polarizers allow more usable light output

Many “dim” displays lose brightness at this stage rather than at the backlight itself.

3. Inefficient Optical Films (Diffuser / Brightness Films)

Optical films control how light is distributed.

-

High-quality films improve light utilization and uniformity

-

Poor-quality films waste a large portion of the light energy

This directly affects perceived brightness and visual clarity.

4. Inadequate Lamination Structure (Air Gap vs Optical Bonding)

-

Air gap (frame bonding):

Causes light refraction and reflection losses -

Optical bonding (OCA / OCR):

Reduces light loss and improves contrast and outdoor readability

5. Unoptimized Display Driver Parameters

Brightness can also be limited by:

-

Driver IC settings

-

PWM dimming configuration

-

Gamma curve calibration

Even capable hardware may appear dim if software parameters are not optimized.

6. Environmental Factors That Reduce Perceived Brightness

Examples include:

-

Direct sunlight

-

Highly reflective cover glass

-

Structural shading from the enclosure

In these cases, the issue is not panel brightness itself, but optical design mismatch.

2. How to Increase LCD Display Brightness: 6 Proven Engineering Solutions

Below are industry-proven brightness enhancement methods, each with clear advantages and trade-offs.

Solution 1: Increase Backlight LED Brightness (Most Effective)

Common approaches:

-

Increase LED quantity

-

Raise LED drive current

-

Use high-efficiency or dual-chip LED

Pros

✔ Maximum brightness improvement

✔ Essential for high-brightness and outdoor LCD

Cons

✘ Higher power consumption

✘ Increased heat

✘ Backlight redesign required

Solution 2: Use High-Transmittance Polarizers

Polarizer transmittance typically ranges from 35% to 44%.

Pros

✔ No additional power consumption

✔ Clearer, more transparent display

Cons

✘ Higher material cost

✘ Requires polarizer replacement process

Solution 3: Add BEF / DBEF Brightness Enhancement Films (Highly Recommended)

BEF (Brightness Enhancement Film):

-

Uses prism structures to focus light

-

Improves brightness by 30%–60%

DBEF (Dual BEF):

-

Recycles polarized light

-

Brightness improvement up to 70%–100%

Pros

✔ No extra power usage

✔ One of the most cost-effective brightness solutions

✔ Widely used in high-brightness LCD designs

Cons

✘ Higher material cost

✘ Strict assembly direction and angle requirements

Solution 4: Optimize Backlight Optical Structure

Upgrading:

-

Diffuser films

-

Reflective sheets

can reduce light loss and improve uniformity.

Pros

✔ Relatively low cost

✔ Better brightness uniformity

Cons

✘ Limited brightness gain

✘ Requires backlight stack-up optimization

Solution 5: Optical Bonding (OCA / OCR)

Replacing air-gap assembly with full optical bonding.

Pros

✔ Brightness improvement of 5%–10%

✔ Higher contrast

✔ Reduced reflection under sunlight

Cons

✘ Higher process complexity

✘ Increased manufacturing cost

Solution 6: Software-Level Optimization (Driver / PWM / Gamma)

Suitable when brightness is artificially limited.

Pros

✔ No hardware cost

✔ Fast implementation

Cons

✘ Limited improvement

✘ Cannot exceed hardware brightness limits

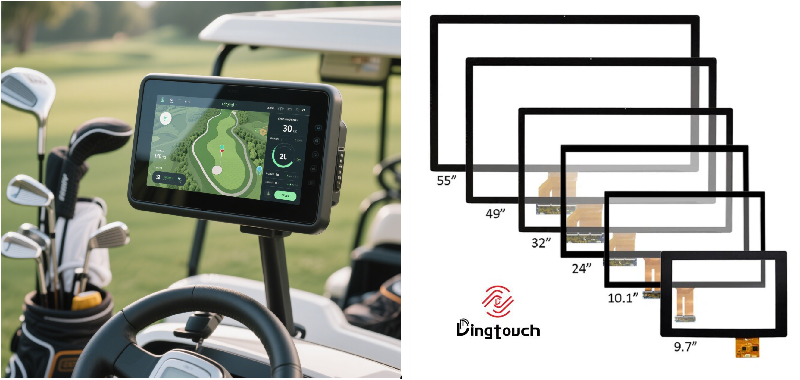

3. LCD Display Too Dim Outdoors? Recommended High-Brightness Combination

Outdoor environments introduce two major challenges:

Strong sunlight

High reflection

Recommended engineering combination:

-

1200–2000 nits high-brightness backlight

-

DBEF dual brightness enhancement film

-

Optical bonding

-

AR / AG / AF surface treatment on cover glass

This solution is widely applied in:

Outdoor terminals, EV charging stations, industrial HMI, medical equipment, and energy systems.

4. Conclusion: LCD Brightness Is a System-Level Engineering Issue

Low LCD brightness is not just a specification issue —

it is the result of backlight design, optical materials, lamination structure, driver configuration, and application environment.

Effective brightness improvement strategies include:

✔ High-brightness backlight (largest impact)

✔ BEF / DBEF optical enhancement films

✔ High-transmittance polarizers

✔ Optimized optical stack-up

✔ Optical bonding to reduce reflection

✔ Fine-tuned driver parameters

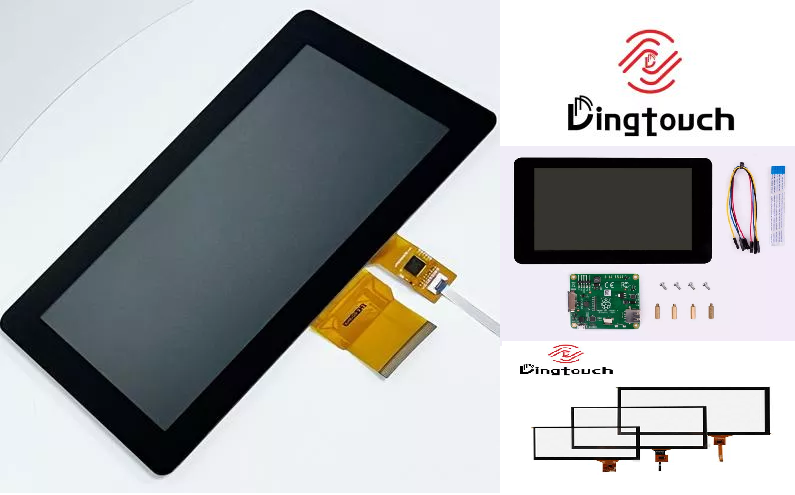

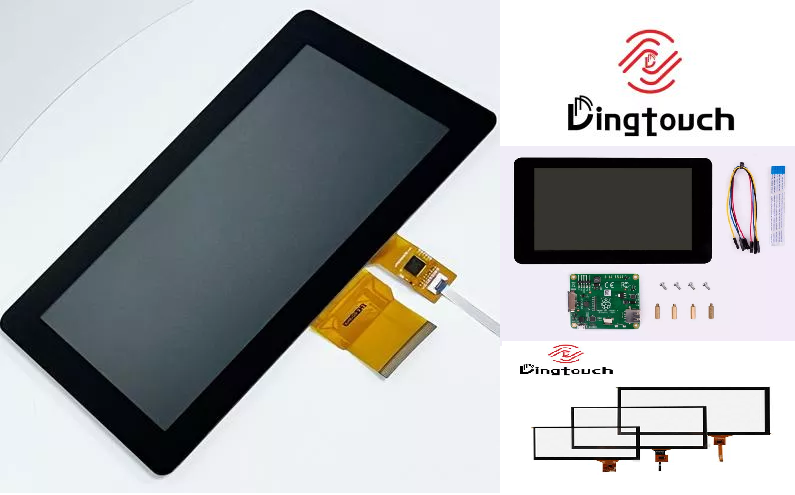

DINGTouch | Engineering High-Brightness LCD & Touch Display Solutions

With 10+ years of experience in LCD and touch display engineering,

DINGTouch delivers more than standard panels:

-

✔ Standard & differentiated LCD solutions

-

✔ High-brightness and outdoor-readable displays

-

✔ Wide-temperature customization

-

✔ Integrated LCD + capacitive touch solutions

-

✔ Engineering support from concept to mass production

Facing brightness challenges in your display project?

Contact DINGTouch technical engineering team and make your display clearly visible — in any environment.

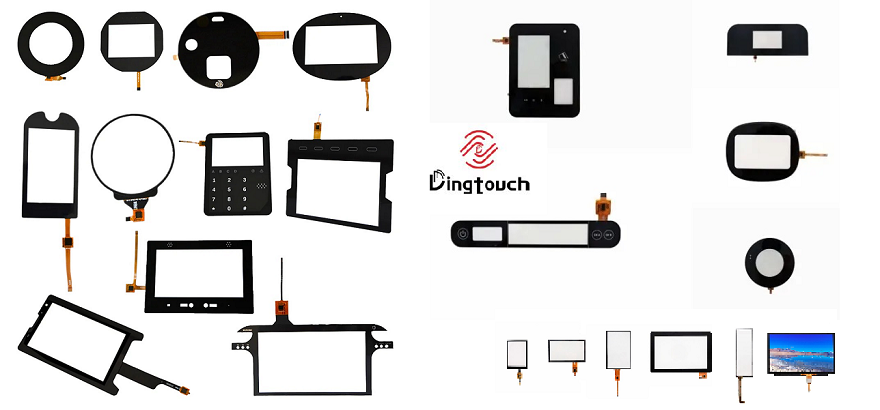

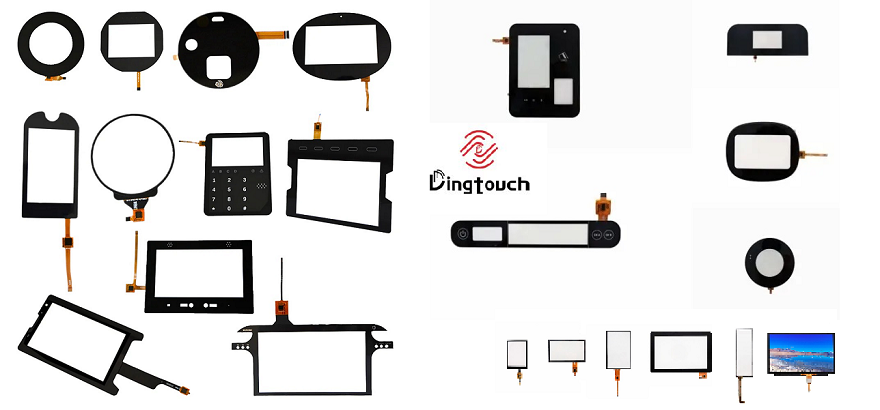

Partner with DINGTouch for Custom Capacitive Touch Solutions

Ready to build your own capacitive touch screen with personalized specifications?

DINGTouch is here to bring your design to life—with precision engineering, premium materials, and industry-leading manufacturing standards.

![]() Email: sales@szdingtouch.com

Email: sales@szdingtouch.com

Website: www.szdingtouch.com

Website: www.szdingtouch.com

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

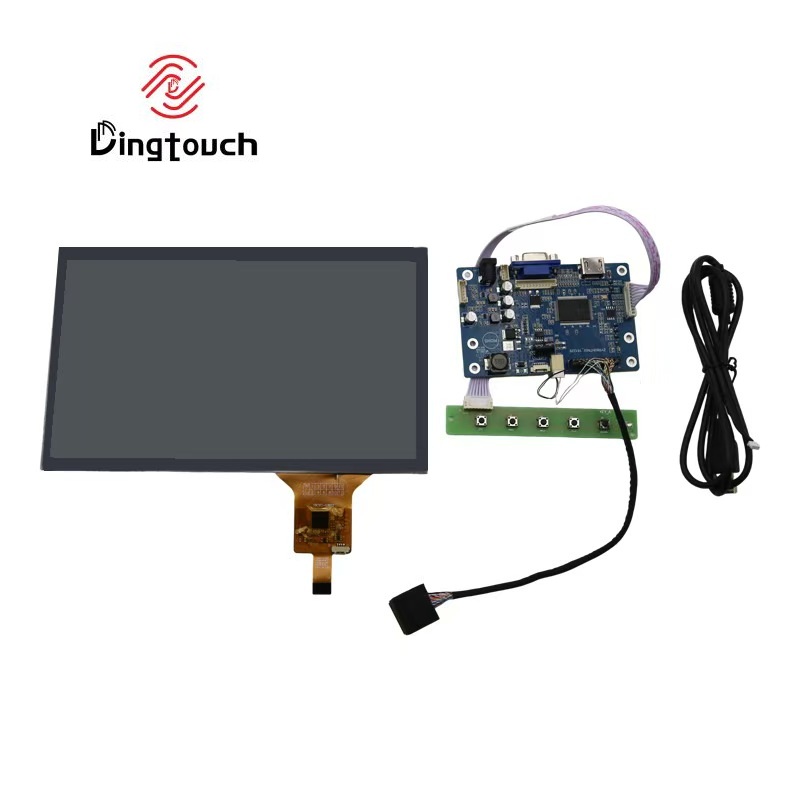

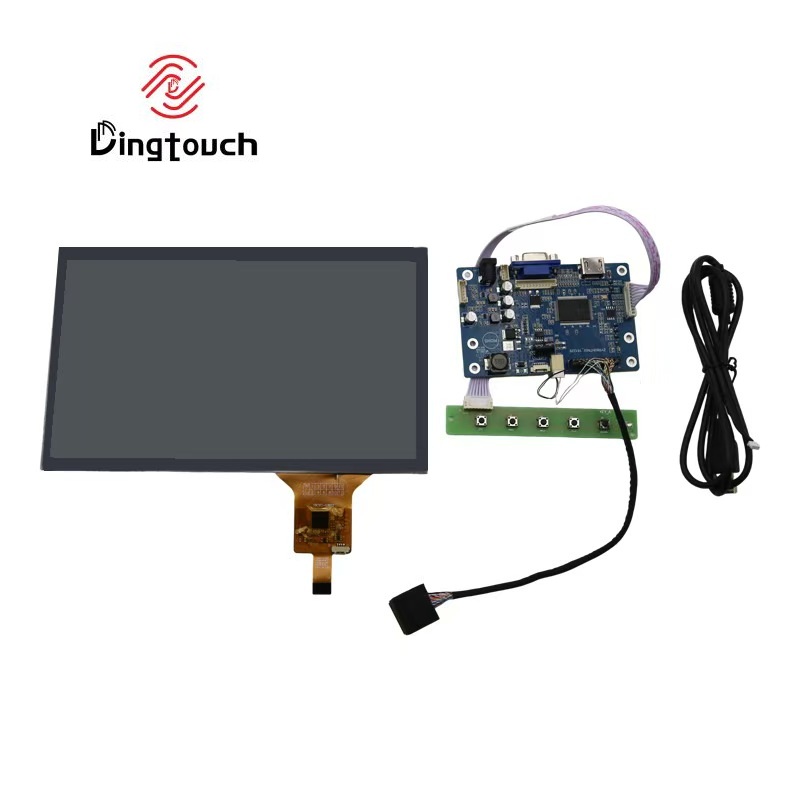

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch