News

Redefining Visual Performance: Exploring the Evolution and Application of Optical Bonding—From OCA to OCR

Redefining Visual Performance: Exploring the Evolution and Application of Optical Bonding—From OCA to OCR

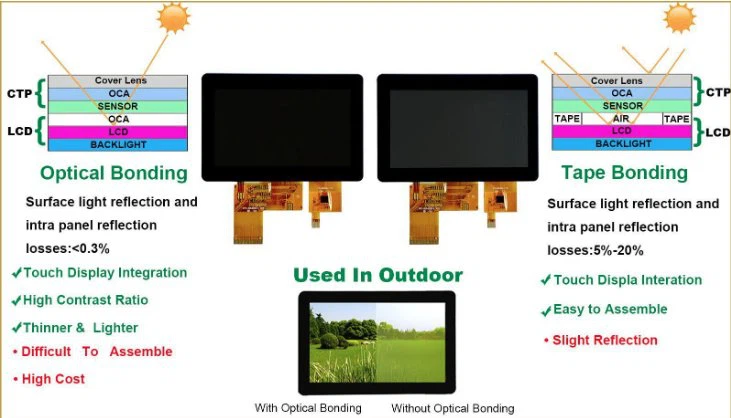

As modern display evolve toward being thinner, brighter, and more intelligent, optical bonding technology has become a key factor in enhancing display performance and user experience. Whether it’s a sun-readable automotive touchscreen or a precision-sensitive medical monitor, a display with superior bonding quality reflects the overall strength of the product.

This article explores the logic behind the development of optical bonding, compares the core materials—OCA (Optically Clear Adhesive) and OCR (Optical Clear Resin/LOCA)—and highlights their benefits, limitations, applications, and emerging trends in the display industry.

1. What Is Optical Bonding and Why Is It Important?

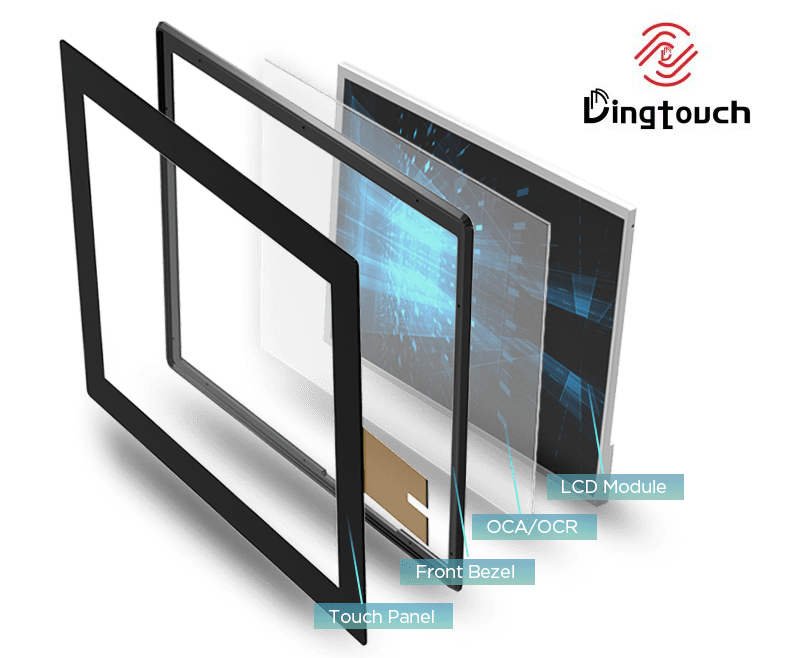

In traditional displays, there's usually an air gap between the touch panel and the display module. This leads to reflections, glare, brightness loss, and makes the screen prone to moisture and dust intrusion. Optical bonding fills this gap with a transparent adhesive, creating a seamless, air-free integration that delivers:

-

Improved sunlight readability

-

Enhanced water, dust, and fog resistance

-

Higher brightness and contrast

-

Better impact and vibration resistance

-

Greater structural integrity and durability

2. Two Main Methods: A Deep Dive into OCA and OCR

OCA: Solid-State Optical Bonding with Double-Sided Adhesive

Material Overview:

OCA is a high-transparency double-sided adhesive film, widely used for bonding small to medium-size displays. Thickness typically ranges from 100μm to 250μm, with custom options available.

Key Advantages:

-

✅ High transmittance (>90%) ensures visual clarity

-

✅ No liquid involved, making the process simple and clean

-

✅ Easy to clean and rework, suitable for quality-sensitive production lines

Limitations:

-

❌ Manual lamination risks air bubbles and wrinkles

-

❌ Poor surface conformity, unsuitable for ITO patterns or larger panels

-

❌ Weaker edge sealing, limited protection against moisture

Ideal Applications:

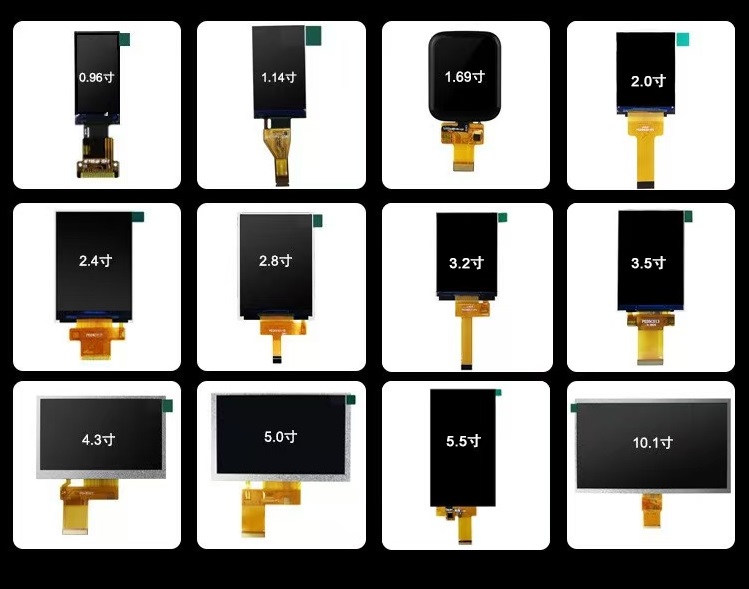

Small consumer electronics, wearable devices, and handheld screens

OCR / LOCA: Liquid Optical Clear Adhesive Bonding

Material Overview:

OCR (also known as LOCA) is a liquid optical adhesive with excellent transparency and flowability, typically cured via UV light or heat. It's designed for complex or framed structures.

Key Advantages:

-

✅ Ultra-high transmittance (>98%), for premium visual quality

-

✅ Fills micro-gaps thoroughly, ensuring seamless bonding

-

✅ Perfect for framed or irregular panel structures

Technical Challenges:

-

❌ More complex process, requiring precise dispensing and control

-

❌ Risk of overflow and air bubbles, especially during alignment and leveling

-

❌ UV curing may miss edges and FPC zones, requiring additional light exposure

Ideal Applications:

Industrial panels, automotive center displays, medical equipment, and large-format interactive displays

3. OCA vs. OCR: Which One Fits Your Project Best?

| Comparison Aspect | OCA (Double-Sided Adhesive) | OCR / LOCA (Liquid Adhesive) |

|---|---|---|

| Transparency | High (>90%) | Ultra-high (>98%) |

| Ease of Use | Simple, easy for mass production | Complex, requires precision control |

| Suitable Sizes | Small / medium displays | Medium / large, irregular surfaces |

| Equipment Cost | Low to medium | Medium to high (UV curing required) |

| Rework Capability | Reworkable | Difficult to rework after curing |

| Cost Efficiency | Lower, ideal for large-scale production | Higher, better suited for premium projects |

| Typical Use Cases | Consumer electronics, wearables | Automotive, medical, industrial use |

4. Future Trends and Innovations in Optical Bonding

As display technologies move toward higher resolution, curved formats, ultra-large sizes, and flexible designs, optical bonding is also evolving. Key trends include:

✅ Rise of Automated Bonding Lines

High-precision automation for dispensing, bonding, and curing is becoming the standard for large-scale production.

✅ Mini/Micro LED Integration

Next-gen displays demand more accurate bonding for fine pixel pitch and direct-emission technologies.

✅ Flexible Optical Adhesives

New materials are being developed to meet the demands of bendable and foldable screens.

✅ High-Protection Custom Solutions

Growing demand for IP65/IP67 waterproofing and IK10 impact protection is pushing innovation in bonding for ruggedized applications.

Conclusion: Bonding Technology as a Gateway to Display Excellence

Optical bonding is more than just a process—it’s an enabler of superior user experience. From OCA simplicity and cost-efficiency to OCR premium quality and adaptability, each bonding method plays a vital role depending on the project’s technical and market requirements.

In today’s visual-driven world, a great display doesn’t just look good—it’s precisely and securely bonded.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medical touchscreen calibration, #capacitive touch calibration guide, #IEC 60601 touchscreen, #DINGTouch medical display, #touch screen accuracy, #touchscreen drift fix, #medical equipment touch solutions, #IP65 touch panel, #IK10 medical touchscreen, #glove touch medical monitor,#ILITEK Touch Controller IC Selection Guide #OCAtoOCR #GT911

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch