News

OCA & OCR Full Lamination Explained: The Technology Behind Crystal-Clear Touch Display Performance

OCA & OCR Full Lamination Explained: The Technology Behind Crystal-Clear Touch Display Performance

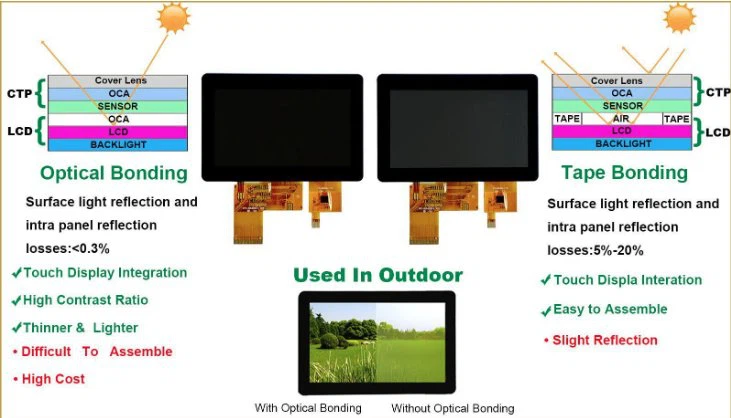

In high-end touch display applications, traditional air bonding methods are rapidly being replaced by full lamination technology, which significantly enhances display clarity, touch responsiveness, and overall durability. Among the leading full lamination solutions are OCA (Optically Clear Adhesive) and OCR (Optically Clear Resin)—each playing a crucial role in industries such as smart terminals, industrial control, medical devices, automotive systems, and large-format commercial displays.

What Is Full Lamination?

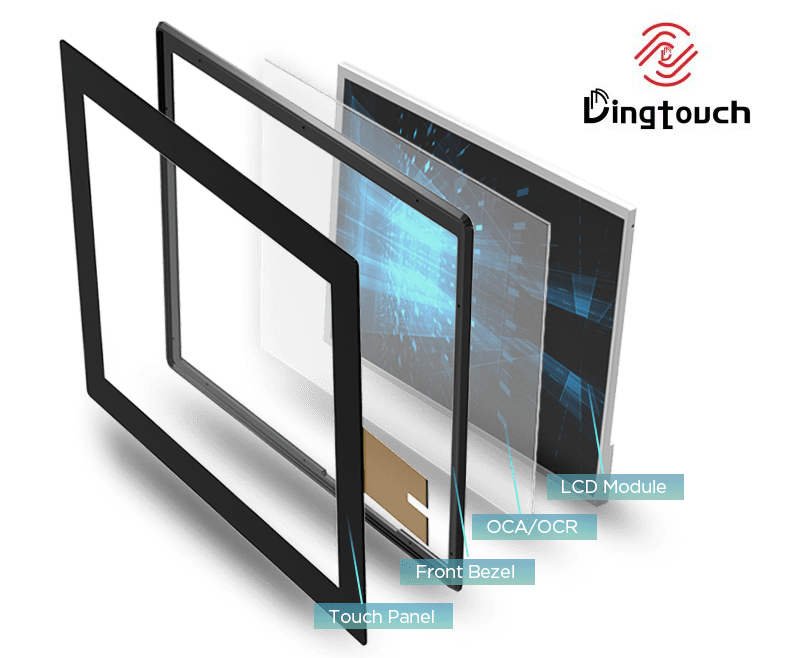

Full lamination refers to the process of bonding the cover glass, touch sensor, and display panel into a seamless, air-gap-free structure. Unlike traditional air bonding, full lamination eliminates internal reflections and improves both the optical and mechanical performance of the screen.

OCA vs OCR: A Comparative Overview

| Feature | OCA (Optically Clear Adhesive) | OCR (Optically Clear Resin) |

|---|---|---|

| Material Form | Solid-state adhesive film | Liquid optical resin |

| Processing Method | Precision alignment + vacuum lamination + UV curing | Dispensing + lamination + UV or heat curing |

| Typical Size Range | Ideal for small to medium sizes (≤21.5") | Suitable for medium to large sizes (>10", up to 65") |

| Optical Properties | High light transmittance, vibrant colors | Excellent clarity, uniform filling, bubble-free |

| Cost Efficiency | Lower cost, widely supported equipment | Slightly higher cost, requires customized control |

| Application Areas | Smartphones, HMI, POS, small devices | Automotive displays, industrial monitors, large screens |

Six Major Advantages of Full Lamination

1. Improved Light Transmission for Brighter, Sharper Display

By eliminating air gaps, full lamination reduces internal reflections and enhances brightness and contrast, ensuring visibility even under strong ambient light—ideal for outdoor, automotive, or industrial environments.

2. Enhanced Touch Accuracy and Responsiveness

With a closer distance between the user's finger and the touch sensor, laminated screens offer faster, more precise touch interaction, especially for multi-touch and edge-based gestures.

3. Better Protection Against Dust and Moisture

The air-tight bonding structure helps prevent dust, fog, or water vapor from entering the screen layers, increasing moisture resistance and durability.

4. Improved Shock Resistance

OCA and OCR bonding layers help absorb impact and reinforce screen structure, reducing the risk of cracking in the event of drops or external force—perfect for rugged or mobile environments.

5. Consistent Visual and Touch Performance

Full lamination ensures uniform display quality and stable touch operation, eliminating visual artifacts such as Newton rings or interference patterns.

6. Supports Advanced Design and Customization

Full lamination is compatible with narrow bezel designs, custom glass printing, and optical coatings (AG/AR/AF), helping brands achieve sleek, premium product appearances.

DINGTouch Full Lamination Solutions

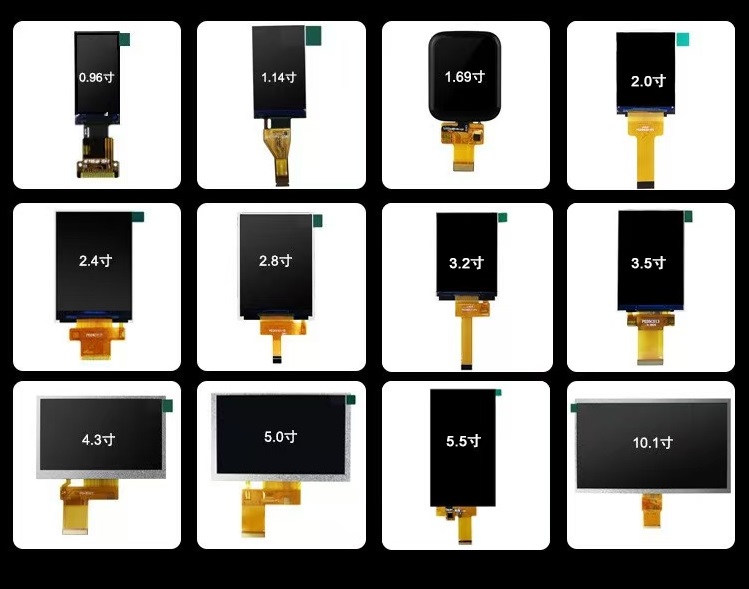

As a leading provider of custom touch display technologies, DINGTouch offers professional OCA and OCR full lamination services, covering screen sizes from 2.8" to 65", tailored to meet the highest industry standards:

-

✅ In-house cleanroom facilities equipped with OCA automation and OCR dispensing systems

-

✅ Supports high-brightness, narrow bezel, and surface treatments (AG/AR/AF)

-

✅ Expert R&D team offering structure design, bonding process consulting, and reliability testing

-

✅ Proven track record in industries such as industrial control, medical equipment, automotive systems, smart terminals, and energy management

Application Scenarios

-

Smart Terminals: Phones, tablets, handheld devices

-

Industrial Control: HMI screens, automation panels, PLC interfaces

-

Automotive Electronics: Center consoles, infotainment systems, digital dashboards

-

Medical Devices: Patient monitors, surgical navigation, diagnostic terminals

-

Self-Service Kiosks: POS terminals, checkout machines, information displays

-

Education & Meeting: Interactive whiteboards, teaching monitors, digital signage

✅ Conclusion: Clearer Vision, Smarter Control, Stronger Screens

OCA and OCR full lamination technologies are revolutionizing the touch display industry by enhancing optical performance, touch functionality, and mechanical reliability. At DINGTouch, we continue to push the boundaries of full lamination to deliver customized, stable, and high-performance solutions across all industries.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medical touchscreen calibration, #capacitive touch calibration guide, #IEC 60601 touchscreen, #DINGTouch medical display, #touch screen accuracy, #touchscreen drift fix, #medical equipment touch solutions, #IP65 touch panel, #IK10 medical touchscreen, #glove touch medical monitor,#ILITEK Touch Controller IC Selection Guide

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch