News

How Industrial Display Support Safety Audits and Regulatory Approval

How Industrial Display Support Safety Audits and Regulatory Approval

An Engineer’s Practical Guide to Documentation, Inspection, and Compliance Readiness

If you have ever participated in a formal safety audit or regulatory approval process, you know it is rarely just about passing technical tests. Auditors are not only verifying compliance—they are evaluating confidence.

They want confidence that the system behaves predictably, communicates clearly, and remains safe under real-world operating conditions.

In that process, the industrial LCD display often becomes one of the most visible and scrutinized components—even when it is not classified as a primary safety device.

This article explains how industrial displays influence safety audits and regulatory approval, drawing from practical engineering experience with documentation reviews, on-site inspections, and compliance assessments.

Table of Contents

Why Do Auditors Focus on Industrial Display?

Why Do Auditors Focus on Industrial Display?

From an auditor’s perspective, the display is the system’s voice.

It is the primary communication interface between machine and operator. When faults occur, when alarms trigger, or when abnormal conditions arise, the display becomes the central point of interaction and interpretation.

Auditors pay close attention to industrial displays because they:

-

Present safety-related information

-

Influence operator decision-making

-

Reflect real-time system states

-

Reveal fault conditions and recovery behavior

Even if the display is not the control logic itself, it directly shapes how safety is perceived and acted upon.

In many audits, reviewers assess not only whether the system is safe—but whether operators can clearly understand that it is safe.

Claim: Displays shape both operational safety and perceived system reliability.

What Display-Related Documentation Is Reviewed During Approval?

In practice, projects rarely fail because a display performs poorly. They fail because the display’s role in safety was insufficiently documented.

Regulatory approval processes rely heavily on traceable documentation that demonstrates engineering intent and risk mitigation.

Typical documentation reviewed during audits includes:

-

Display datasheets and electrical specifications

-

Brightness, contrast ratio, and readability justification

-

Environmental ratings (temperature, humidity, vibration)

-

EMC/EMI compliance evidence

-

Failure mode behavior descriptions

-

Power-loss and restart characteristics

-

HMI functional descriptions and alarm logic mapping

If brightness is selected for outdoor operation, auditors may ask:

Why this luminance level? What is the visibility margin?

If the display supports alarms, they may ask:

How are alarm priorities differentiated? What happens if the display fails?

Clear documentation reduces ambiguity and builds credibility.

Claim: If a safety-related behavior is not documented, auditors assume it was not engineered intentionally.

For this reason, industrial LCD screen with clear specifications, revision traceability, and environmental certifications significantly simplify audit preparation.

What Do Auditors Evaluate During On-Site Inspections?

On-site audits are often less about measurement and more about observation.

Inspectors rarely bring instruments to measure luminance or contrast. Instead, they evaluate system behavior under real-world and simulated fault conditions.

Common inspection focus areas include:

1. Alarm Visibility and Clarity

Are warnings distinguishable?

Are critical alarms clearly prioritized?

Is color usage consistent and justified?

2. Behavior During Power Loss

What does the display show after restart?

Does it return to a safe default state?

Is system status clearly indicated?

3. Consistency Between Documentation and Reality

Does the actual interface match documented behavior?

Are labels and terminology consistent?

4. Operator Interaction Under Simulated Faults

Can operators quickly interpret abnormal conditions?

Is recovery guidance clear?

Auditors place significant weight on observed behavior.

Claim: Observed system behavior builds more trust than written compliance claims.

touchscreens?maximizing="" precision:="" next-generation="" medical="" devices="" powered="" by="" dingtouch="" medical-grade="" custom="" touchscreens"="">

touchscreens?maximizing="" precision:="" next-generation="" medical="" devices="" powered="" by="" dingtouch="" medical-grade="" custom="" touchscreens"="">

How Engineers Can Prepare Displays for Regulatory Approval

touchscreens?maximizing="" precision:="" next-generation="" medical="" devices="" powered="" by="" dingtouch="" medical-grade="" custom="" touchscreens"="">

touchscreens?maximizing="" precision:="" next-generation="" medical="" devices="" powered="" by="" dingtouch="" medical-grade="" custom="" touchscreens"="">

From an engineering standpoint, successful audits are rarely dramatic—they are predictable.

Approval depends on systems behaving exactly as described in the documentation, especially under stress conditions.

Practical preparation steps include:

Align HMI Design With Safety Assumptions

Ensure alarm logic, system states, and displayed information match risk assessment documentation.

Demonstrate Stable Operation Under Environmental Stress

Verify display readability across operating temperature ranges.

Confirm no flicker, distortion, or abnormal reset behavior.

Standardize Alarm Presentation

Use consistent color coding, icons, and wording.

Avoid ambiguous terminology.

Validate Fail-Safe Behavior

Confirm how the display behaves during communication loss or power interruption.

Train Operators

Auditors often ask operators to explain displayed information.

Well-trained operators strengthen audit confidence.

Claim: Regulatory approval is earned through predictable, repeatable system behavior.

At DINGTouch, display design for industrial applications considers not only optical performance and durability, but also documentation traceability and compliance alignment—key factors in safety audits.

Conclusion: Predictability Builds Auditor Confidence

Industrial display play a visible and influential role in safety audits and regulatory approval processes.

They:

-

Communicate system intent

-

Reveal system behavior under stress

-

Influence operator decision-making

-

Shape overall confidence in compliance

Passing audits is not about minimizing complexity or hiding edge cases. It is about ensuring that system behavior is clear, consistent, and defensible.

As part of the DINGTouch industrial LCD screen engineering knowledge framework, this guide reflects a practical truth from real-world inspections:

Auditors approve systems they can understand, observe, and trust.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

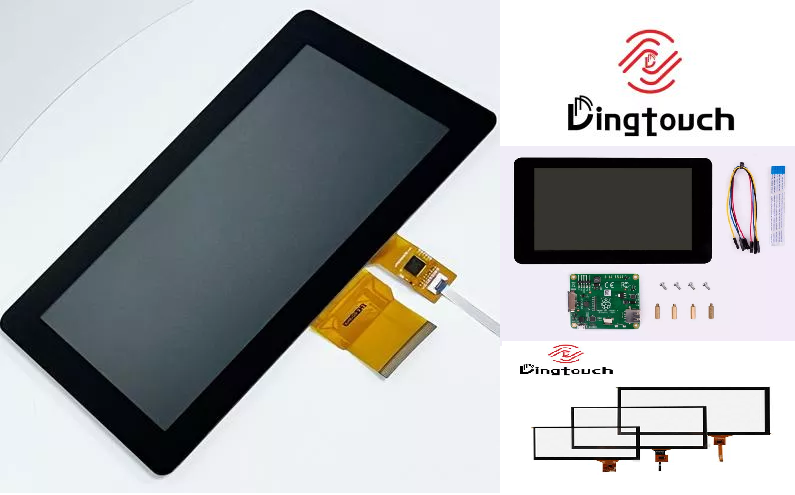

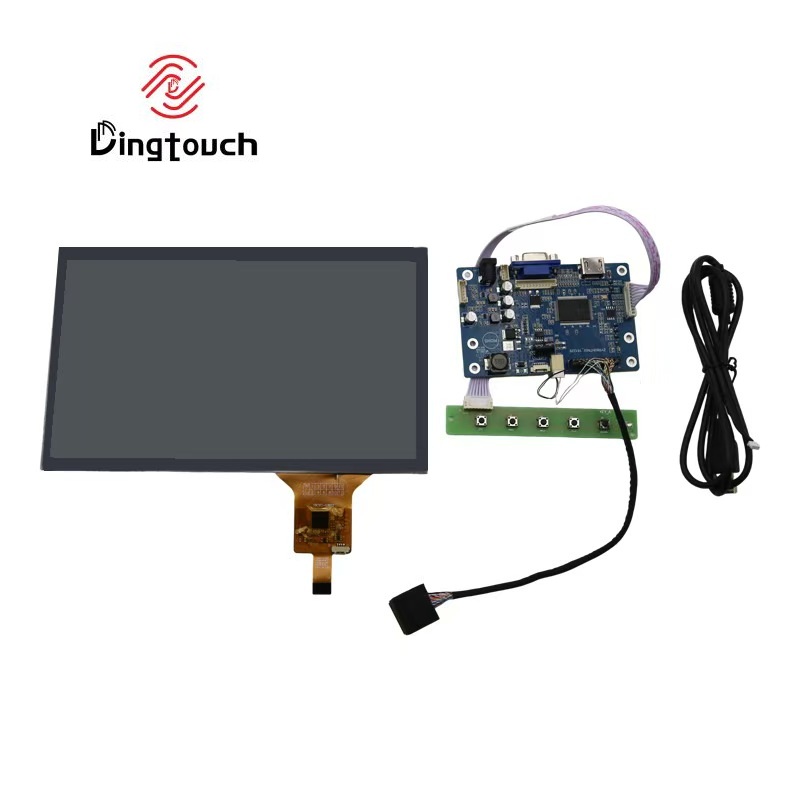

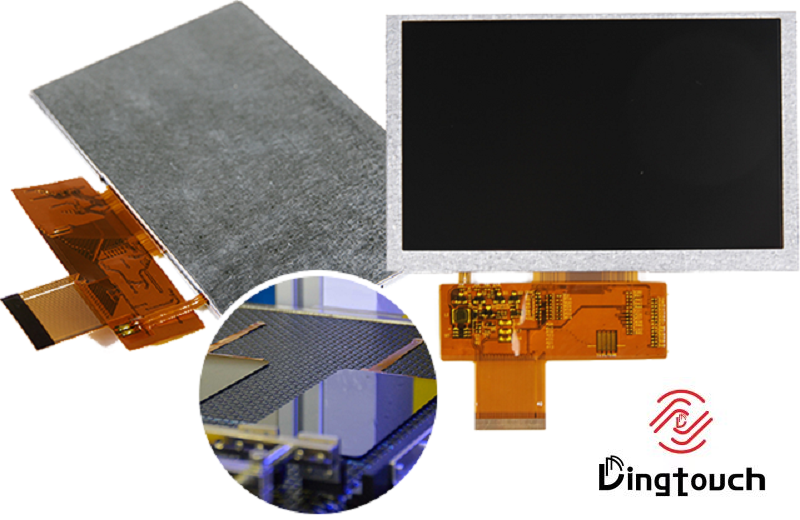

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch