News

A Comprehensive Guide to Display Cover Glass

A Comprehensive Guide to Display Cover Glass

From Materials and Manufacturing Processes to Functional Coatings and Future Trends

I. Overview of Cover Glass: Definition and Core Value

1. What Is Display Cover Glass?

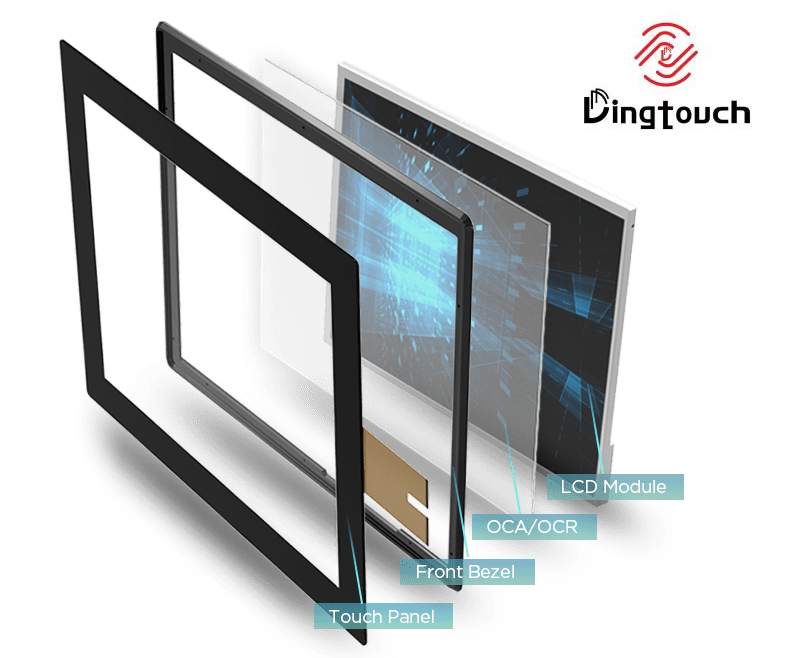

Display cover glass is the transparent protective layer positioned on the outermost surface of display devices such as smartphones, tablets, industrial monitors, automotive displays, and self-service terminals.

Core Materials

-

High-strength glass (mainstream choice)

-

Specialized transparent polymers (for lightweight or flexible applications)

2. Core Functions and Value of Cover Glass

Cover glass is far more than a simple protective layer—it is a critical carrier of functionality, performance, and user experience:

-

Physical Protection

Protects the underlying touch panel (TP) and display module (LCD / OLED) from scratches, impacts, and daily wear -

Touch Interface

Provides a smooth, responsive, and stable surface for touch interaction -

Optical Window

Ensures high light transmittance and low reflectance for accurate colors, sharp images, and clear visibility -

Design Platform

Supports 2.5D / 3D curved edges, decorative silk printing, anti-glare, and anti-fingerprint functional designs

II. Manufacturing Foundation: The Origin of Cover Glass

1. Glass Substrate — Formation of the “Raw Glass Sheet”

The starting point of cover glass manufacturing is unstrengthened, unprocessed glass sheets, commonly referred to in the industry as raw glass.

Primary Raw Materials

-

Silica sand (SiO₂, main component)

-

Soda ash (Na₂CO₃)

-

Limestone (CaCO₃)

-

Feldspar and other auxiliary materials

Basic Manufacturing Process

Raw material batching → High-temperature melting (>1500°C) → Homogenization and fining → Forming → Annealing and cooling

2. Comparison of Two Mainstream Glass Forming Technologies

| Aspect | Float Process | Overflow Down-Draw Process |

|---|---|---|

| Principle | Molten glass floats on molten tin and forms under gravity and surface tension | Molten glass flows down from both sides of an overflow trough and fuses at the bottom |

| Surface Condition | One side contacts tin, the other contacts atmosphere | Both sides are pristine surfaces with no contact |

| Key Features | Lower cost, good flatness, widely used | Exceptional purity, flatness, and mechanical strength |

| Typical Applications | Mid-range and general-purpose cover glass | High-end consumer electronics, industrial and automotive cover glass |

| Representative Manufacturers | AGC, NSG, CSG, Xinyi | Corning (Gorilla Glass), SCHOTT |

Conclusion

![]() The overflow down-draw process is the preferred choice for high-end cover glass applications.

The overflow down-draw process is the preferred choice for high-end cover glass applications.

III. From Raw Glass to Finished Cover Glass: Key Processing Steps

Overall Manufacturing Flow

Raw glass → CNC machining → Pre-grinding → Cleaning → Chemical strengthening → Post-grinding → Post-processing (silk printing / coating) → Inspection and packaging

1. CNC Shape Machining

Purpose

-

Precisely cut the final outline and dimensions

-

Create openings for speakers, cameras, buttons, and sensors

Equipment

-

High-precision CNC machines

-

Diamond cutting tools

2. Grinding and Polishing Processes

Purpose

-

Precisely control glass thickness

-

Improve surface flatness and smoothness

-

Eliminate cutting marks, micro-cracks, and residual stress

Process Types

-

Pre-grinding: thickness control before strengthening

-

Post-grinding: contour refinement after strengthening

3. Core Process: Chemical Strengthening

Principle

The glass is immersed in molten potassium nitrate (KNO₃) at high temperature, allowing sodium ions (Na⁺) in the glass surface to be replaced by potassium ions (K⁺).

Strengthening Effects

-

Larger K⁺ ions are forced into the glass surface

-

A strong surface compressive stress layer (CS) is formed

-

A corresponding internal tensile stress layer develops

-

Overall glass strength increases by several times to dozens of times

Key Parameters

-

Surface compressive stress (CS)

-

Depth of layer (DOL)

4. Cleaning, Silk Printing, and Post-Processing

-

Ultrasonic cleaning and drying: removes particles, oils, and ionic residues

-

Silk printing and decoration:

-

Light blocking

-

Concealment of internal structures

-

Enhanced aesthetic appearance

-

IV. Functional Surface Coating Technologies

IV. Functional Surface Coating Technologies

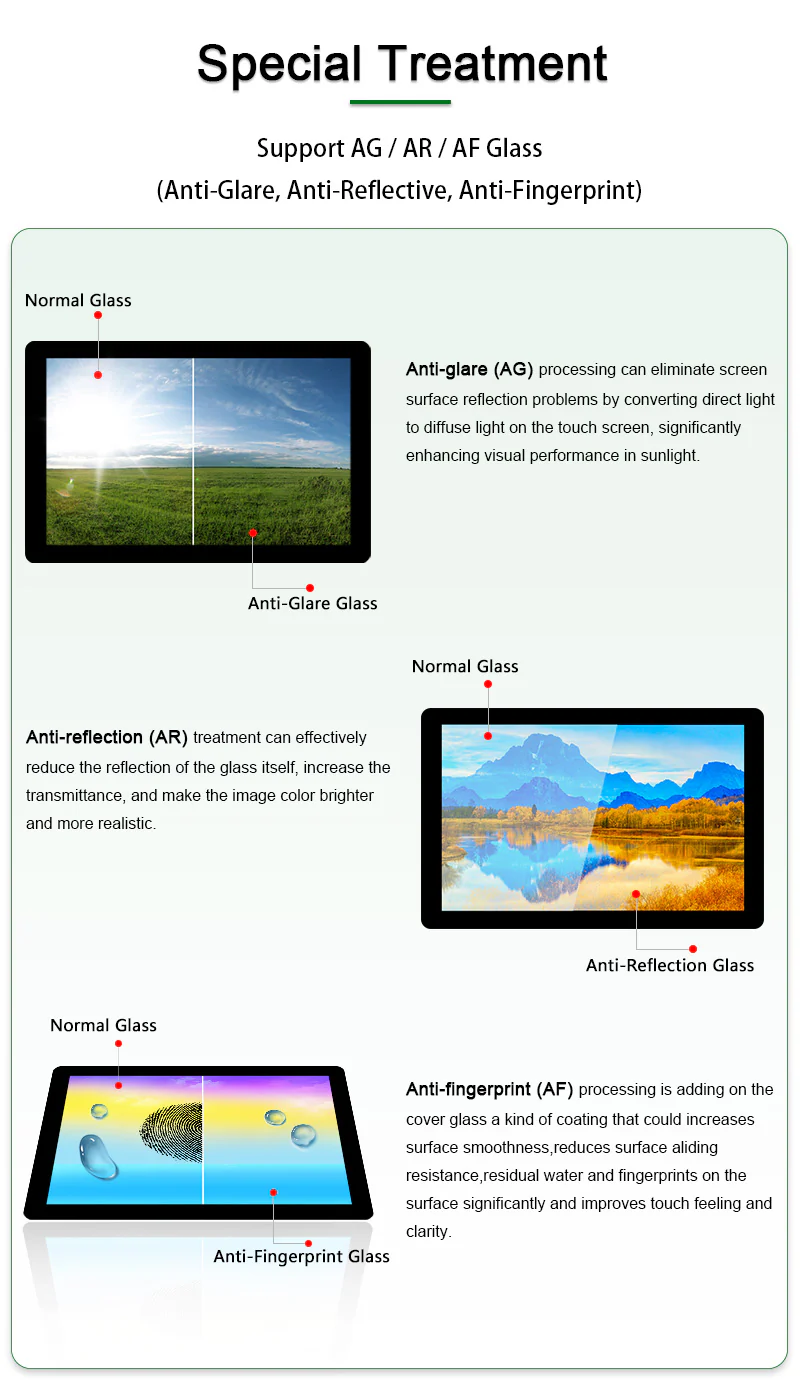

1. AG (Anti-Glare)

-

Problem Addressed: Severe screen glare under strong ambient light

-

Principle: Micro-textured surface converts specular reflection into diffuse reflection

-

User Benefit: Clear readability even in outdoor or high-light environments

2. AR (Anti-Reflection / Anti-Reflective)

-

Problem Addressed: Reflection reduces contrast and color saturation

-

Principle: Optical interference coatings cancel reflected light waves

-

User Benefit: Higher contrast, richer colors, and a “glass-free” visual experience

3. AF (Anti-Fingerprint)

-

Problem Addressed: Fingerprints and oil residue accumulation

-

Principle: Fluorinated nano-scale hydrophobic and oleophobic coating (lotus effect)

-

User Benefit: Smoother touch, easier cleaning, and improved durability

Industry Trend

![]() AR + AF composite coatings have become standard in mid-to-high-end devices.

AR + AF composite coatings have become standard in mid-to-high-end devices.

V. Reliability Validation: Ball Drop Impact Test

1. Test Method

A steel ball of specified material and mass is dropped freely from a fixed height onto designated positions of the cover glass (center or weakest area).

2. Impact Energy Calculation

Formula

E=m×g×hE = m \times g \times hE=m×g×h-

E: Impact energy (J)

-

m: Mass of the steel ball (kg)

-

g: Gravitational acceleration (9.8 m/s²)

-

h: Drop height (m)

3. Acceptance Criteria

-

No cracks or breakage after testing

-

Or crack length within specified limits

-

Requirements vary by application (consumer, industrial, automotive)

VI. Technology Trends and Future Evolution

1. Evolution of Cover Glass Form Factors

2D flat → 2.5D curved edge → 3D curved glass → Foldable UTG (Ultra-Thin Glass)

2. New Material Directions

-

Glass-Ceramics: Significantly higher hardness and toughness, offering major improvements in drop resistance

-

Sapphire Glass: Exceptional scratch resistance, but higher cost and weight, mainly used in camera covers and high-end watches

3. Industry Challenges and Future Outlook

Challenges

-

Achieving thinner, lighter, and more curved designs while maintaining or enhancing strength

Future Trends

-

Deep integration with display technologies (under-display cameras, Micro-LED)

-

Integration of sensing functions (fingerprint recognition, pressure sensing)

-

Cover glass is evolving from a protective component into an intelligent interaction platform

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

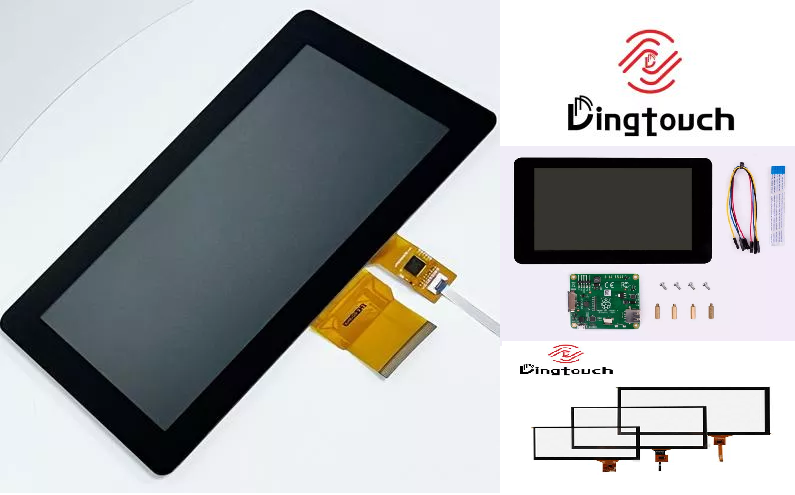

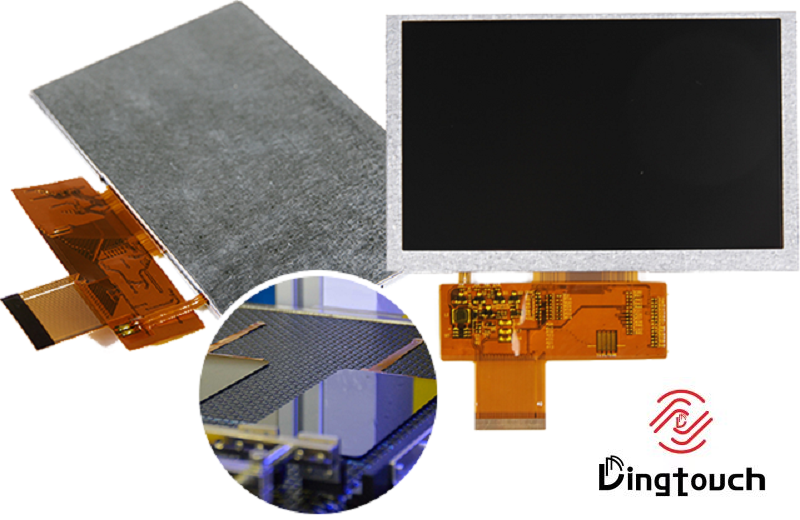

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

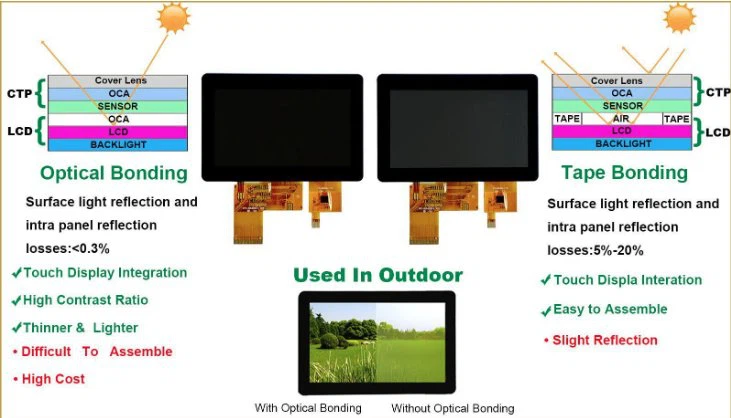

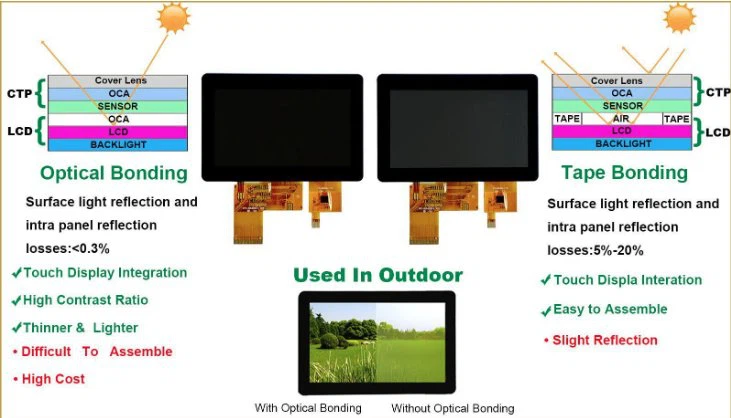

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch