News

What Is Optical Bonding: The Key Technology to Enhance Display Performance and Reliability

What Is Optical Bonding: The Key Technology to Enhance Display Performance and Reliability

Table of Contents

- Introduction

- What Is Optical Bonding?

- How Optical Bonding Works

-

Key Advantages of Optical Bonding

4.1 Enhanced Display Performance

4.2 Mechanical Strength and Environmental Protection - Optical Bonding vs. Air Bonding

- Typical Applications of Optical Bonding

- Conclusion and Outlook

1. Introduction

In the evolution of modern display technology, optical bonding has become a critical process for improving both performance and reliability. Whether in industrial automation systems, medical monitors, automotive dashboards, or outdoor terminals, users are demanding clearer visuals and more robust structural integrity.

The overall performance of a display module is determined not only by the brightness and resolution of the panel itself but also by the bonding method between the cover glass and the LCD module. This often-overlooked process directly impacts sunlight readability, impact resistance, and long-term durability.

By eliminating the air gap between display layers, optical bonding technology achieves superior optical clarity and environmental resilience. This article explores the definition, working principle, advantages, and diverse applications of optical bonding technology.

2. What Is Optical Bonding?

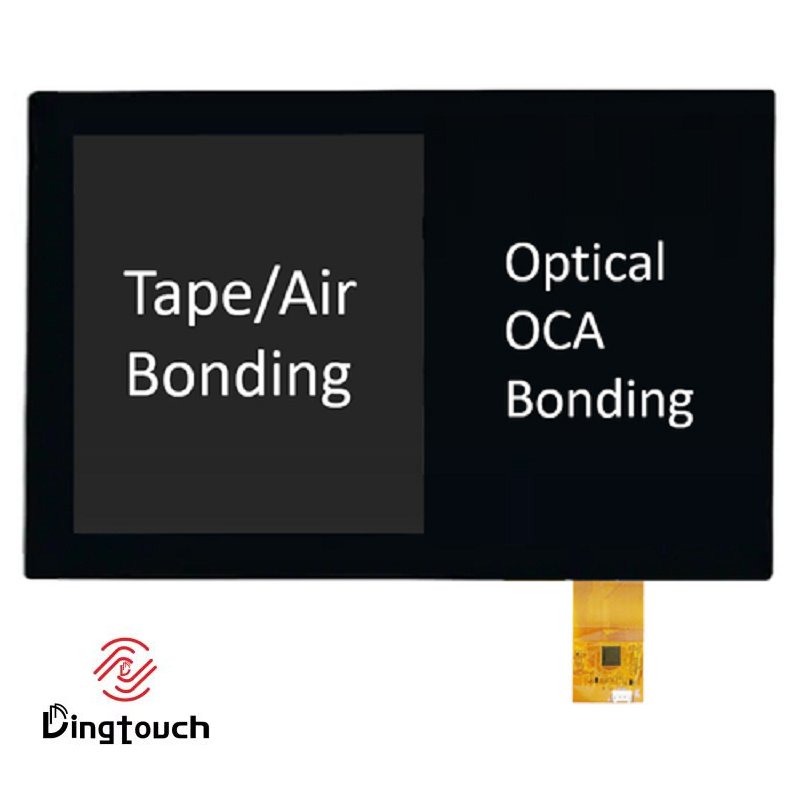

Optical bonding is a lamination process that directly bonds the cover glass (or touch panel) to the LCD display module using a high-transparency optical adhesive, typically OCA (Optically Clear Adhesive) or OCR (Optically Clear Resin). The adhesive fills the microscopic gap between layers, forming a single, optically unified structure.

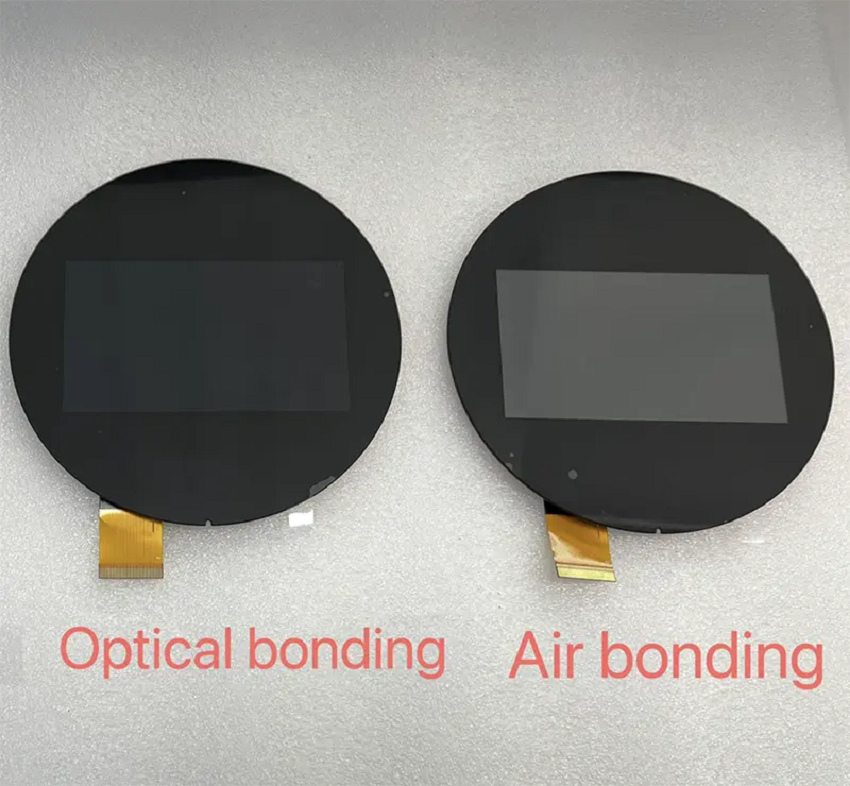

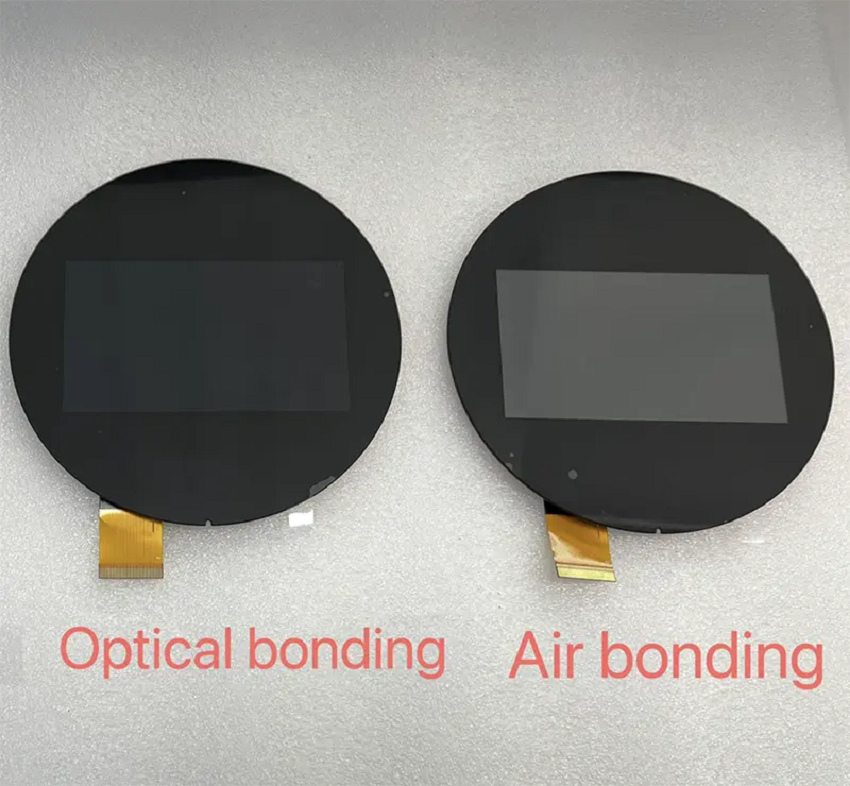

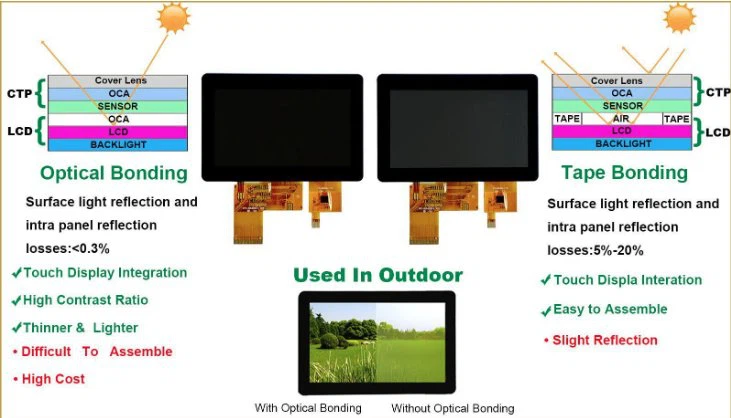

In traditional air bonding, a thin layer of air remains between the cover glass and LCD. This air gap causes internal reflection, refraction, and glare. Optical bonding eliminates this issue, allowing light to pass through the display stack with minimal loss—thereby enhancing brightness, contrast, and color accuracy.

Additionally, optical bonding can make devices thinner and lighter while significantly improving impact resistance and durability. For this reason, it is often referred to as “full lamination” or “seamless bonding” technology.

3. How Optical Bonding Works

Optical bonding involves creating a transparent and durable connection among three main components:

- Cover Glass or Touch Panel: Protects the display and provides the touch interface.

- Optical Adhesive (OCA/OCR): Fills the gap, transmits light, and enhances structural stability.

- LCD Display Module: Displays the image output.

In an air-bonded display, light reflects multiple times between the glass-air and air-LCD interfaces, reducing visibility. By removing the air layer, optical bonding minimizes internal reflection by up to 90%, creating a purer light path and improving clarity.

Since the refractive index of OCA/OCR closely matches that of glass, light transmission efficiency increases—resulting in higher brightness and contrast. From a touch perspective, removing the air gap also reduces parallax, ensuring perfect alignment between the display image and touch point, creating a more natural and accurate touch experience.

4. Key Advantages of Optical Bonding

4.1 Enhanced Display Performance

- Superior Outdoor Readability: Dramatically reduces reflection and glare for excellent sunlight visibility.

- Higher Contrast and Color Accuracy: Improves light transmission efficiency for vivid, true-to-life images.

- More Precise Touch Experience: No air gap means more accurate, responsive touch performance.

- Reduced Haze and Light Interference: Ensures sharper and clearer image quality.

4.2 Mechanical Strength and Environmental Protection

- Improved Impact and Vibration Resistance: The adhesive layer absorbs stress and protects the LCD.

- Excellent Moisture, Dust, and Fog Resistance: No air gap prevents particle and moisture intrusion.

- Enhanced Environmental Durability: Performs reliably under extreme temperature, humidity, and altitude conditions.

- Extended Service Life: Ensures long-term stability and reliability in critical applications such as industrial and medical systems.

5. Optical Bonding vs. Air Bonding

| Feature | Optical Bonding | Air Bonding |

|---|---|---|

| Reflectivity | Low (better visibility) | High (causes glare) |

| Light Transmission | Higher | Lower |

| Cost | Higher | Lower |

| Moisture/Dust Protection | Excellent | Poor |

| Structural Strength | High | Average |

| Maintenance | More difficult to disassemble | Easier to maintain |

For outdoor kiosks, vehicle displays, and industrial control panels, where visibility and durability are crucial, optical bonding is the ideal choice. However, for indoor or cost-sensitive applications, such as tablets or general-purpose displays, air bonding remains an economical solution.

6. Typical Applications of Optical Bonding

Optical bonding technology is widely used in professional environments that demand high contrast, durability, and protection, including:

- Industrial HMI Panels: Dustproof, vibration-resistant, and suitable for factory automation systems.

- Medical Display Monitors: Ensure clear, accurate visuals for surgical and patient monitoring systems.

- Outdoor Terminals: ATM, ticket machines, and kiosks benefit from high visibility and weather resistance.

- Automotive and Aerospace Displays: Designed to withstand temperature changes, vibration, and direct sunlight.

- Smart Home and Commercial Displays: Provide sleek aesthetics with immersive touch interaction.

Across these sectors, optical bonding not only enhances visual performance but also significantly strengthens device reliability and user confidence.

7. Conclusion and Outlook

Optical bonding is rapidly becoming the industry standard for high-reliability display module design. While its manufacturing cost is higher than air bonding, its advantages in performance, lifespan, and user experience make it indispensable in industrial, medical, automotive, and outdoor display applications.

As optical adhesive materials, automated lamination equipment, and bonding precision continue to advance, optical bonding is becoming more efficient and cost-effective. In the near future, this technology will integrate with high-brightness backlights, anti-reflective coatings, and IK10-rated protective glass, setting new standards in display innovation.

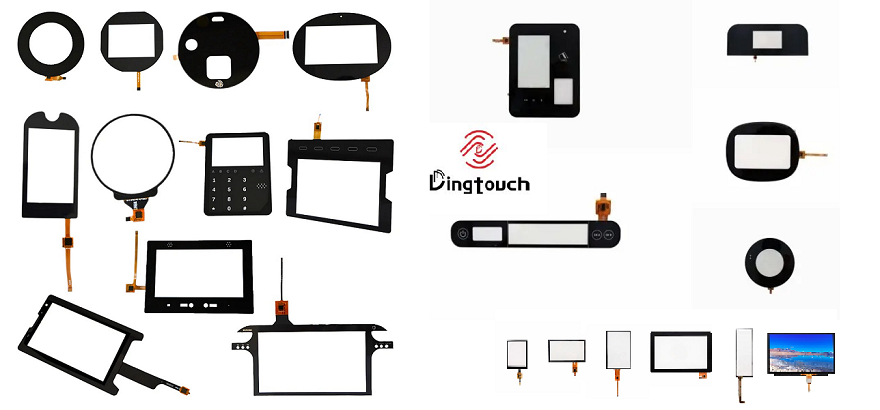

DINGTouch: Empowering Your Display Projects with Custom Excellence

As a professional manufacturer specializing in custom capacitive touchscreen and display modules, DINGTouch has successfully supported projects across industrial control, medical devices, smart homes, commercial displays, and automotive systems.

We offer:

- ✅ Custom Touch Display Solutions (ranging from 2.8” to 65”)

- ✅ Multiple Structures: G+G, G+F+F, Full Lamination / Air Bonding

- ✅ Multi-Interface Options: I2C, USB, SPI, RS485, UART, and more

- ✅ High-Brightness, Anti-Reflective, and IK10-Protected Designs

- ✅ Personalized, Differentiated, and Special-Spec Customization Services

With deep industry expertise and strict quality control, DINGTouch helps clients turn design concepts into mass-production success, delivering tailored touch display solutions that perfectly fit their applications.

![]() Contact the DINGTouch Technical Team:

Contact the DINGTouch Technical Team:

sales@szdingtouch.com

Let’s create the next generation of high-performance touch display products—where innovation meets precision.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedical display, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions, #Waterproof Touchscreen

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch