News

Thermal Management in Industrial Display: The Key to Ensuring Performance and Reliability

Thermal Management in Industrial Display: The Key to Ensuring Performance and Reliability

In harsh industrial environments, display devices must deliver not only outstanding visual performance but also long-term operational stability under extreme conditions. High temperatures, humidity, dust, and continuous workloads put significant pressure on display systems. Among all these challenges, thermal management stands out as one of the most critical factors affecting the performance and lifespan of industrial-grade displays.

If thermal design is inadequate, overheating can cause reduced performance, color degradation, shortened lifespan, or even permanent display failure. This article explores the importance of thermal management and the various techniques used to enhance reliability and stability in industrial displays.

1. Importance of Thermal Management

High temperature significantly affects the electrical characteristics and physical structure of electronic components. For industrial displays that operate continuously, effective heat control is vital for several reasons:

-

Image Retention (Burn-in)

Prolonged exposure to high temperature can alter the structure of liquid crystal or organic light-emitting materials, leading to persistent image retention or “burn-in” effects on the screen. -

Color Degradation

Excessive heat can change the chemical stability of display materials, resulting in color shifts, brightness loss, and overall image quality degradation. -

Component Failure

Transistors, capacitors, resistors, and integrated circuits are highly sensitive to heat. Elevated temperatures accelerate aging and may lead to circuit breakdown or total device failure.

Therefore, efficient thermal management is essential to maintain optimal performance and extend the service life of industrial display.

2. Common Thermal Management Techniques in Industrial Display

To combat heat buildup, industrial display systems employ a variety of thermal management methods, often combining several techniques for the best results:

-

Heatsinks

Made from aluminum or copper, heatsinks dissipate heat from key components such as driver ICs and backlight modules by increasing the surface area for heat transfer.

In DINGTouch industrial display designs, heatsinks often feature CNC-machined one-piece structures for superior thermal conductivity and mechanical strength. -

Active Cooling Fans

For high-power or enclosed systems, active cooling fans generate forced airflow to reduce internal temperatures.

Some systems integrate intelligent temperature sensors to automatically adjust fan speed for optimal noise control and energy efficiency. -

Heat Pipes and Vapor Chambers

These technologies use phase-change principles—evaporation and condensation—to rapidly transfer heat away from components.

Vapor chambers are particularly effective in ultra-thin display modules or touch all-in-one systems, ensuring uniform temperature distribution. -

Thermal Interface Materials (TIM)

High-conductivity materials such as thermal grease, pads, or graphite sheets form efficient heat paths between chips and heatsinks, minimizing thermal resistance and improving heat transfer efficiency. -

Enclosure and Ventilation Design

Industrial displays often feature metal housings with optimized vent structures to enhance passive heat dissipation.

For devices requiring high protection ratings (e.g., IP65 or IP67), DINGTouch employs sealed thermal conduction designs that balance heat dissipation with dust and water resistance.

3. Systematic Approach to Thermal Design

Effective thermal management is not about improving a single component—it is the result of an integrated system design.

At DINGTouch, thermal simulation analysis is performed during the early design phase to evaluate heat flow and temperature distribution across the entire system. This helps optimize heatsink geometry, material selection, and component layout.

Furthermore, DINGTouch tailors thermal solutions for specific application environments—such as high-temperature factories, outdoor control cabinets, or transportation systems—to ensure reliable operation under even the harshest conditions.

4. Conclusion: Thermal Management as the Foundation of Reliability

Thermal control directly impacts not only the performance but also the overall reliability of industrial displays. By integrating heatsinks, fans, heat pipes, and thermal interface materials, modern industrial display systems can maintain stable operation and long service life in extreme environments.

As a professional manufacturer of custom touchscreen and display solutions, DINGTouch regards thermal management as a fundamental element of product design—offering customers high-reliability, long-lifespan industrial displays engineered for 24/7 operation.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

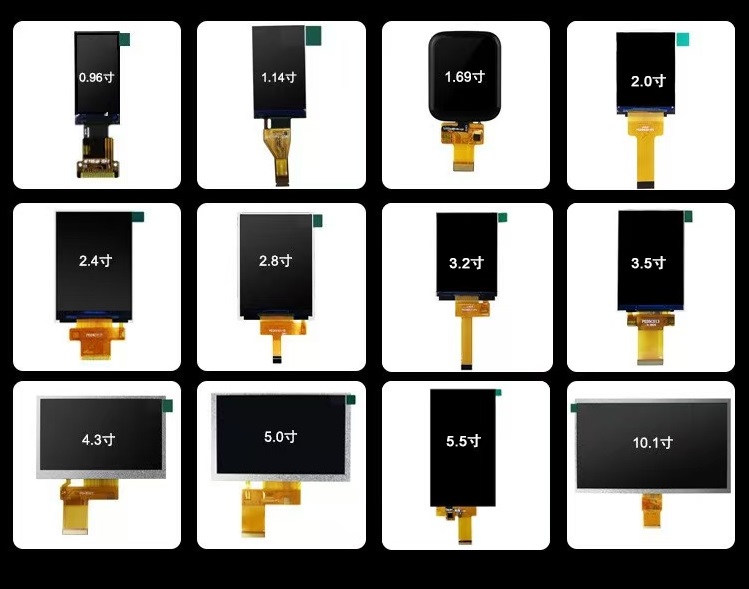

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedical display, #touchscreenaccuracy, #touchscreen drift fix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions

Find the DINGTouch technical team to achieve the success of your company's new project.

What DINGTOUCH can do:

Dingtouch Industrial Capacitive Touch Screen Manufacturer

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch