News

Root Cause Analysis of Functional Failures in Film-Structure Touch Modules After Full Lamination or Frame Bonding

Root Cause Analysis of Functional Failures in Film-Structure Touch Modules After Full Lamination or Frame Bonding

— ITO Cracking Mechanisms and Manufacturing Control Strategies | DINGTouch Engineering Practice

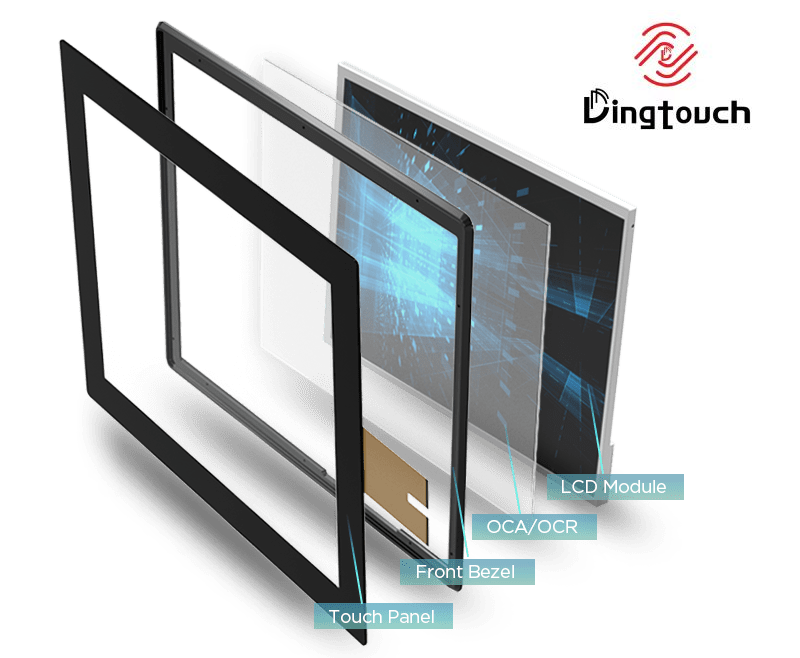

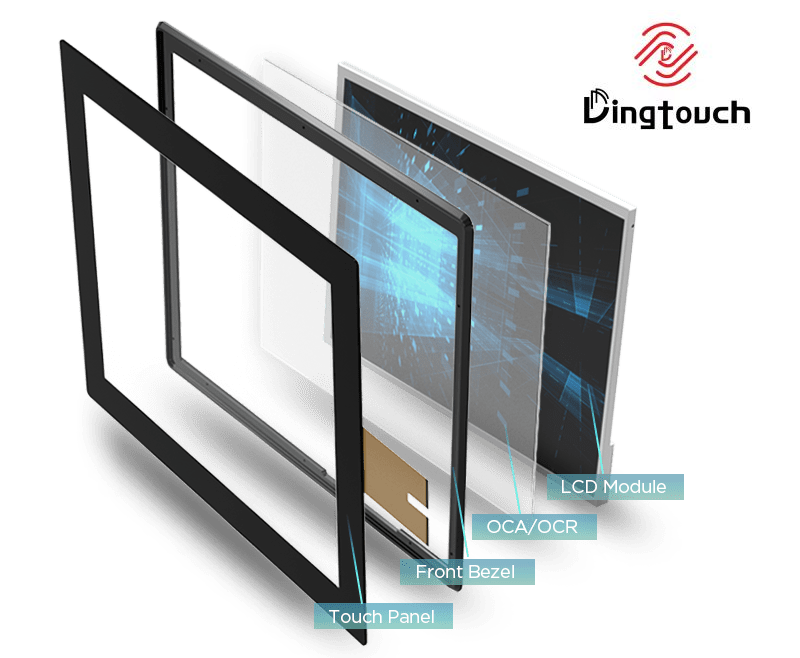

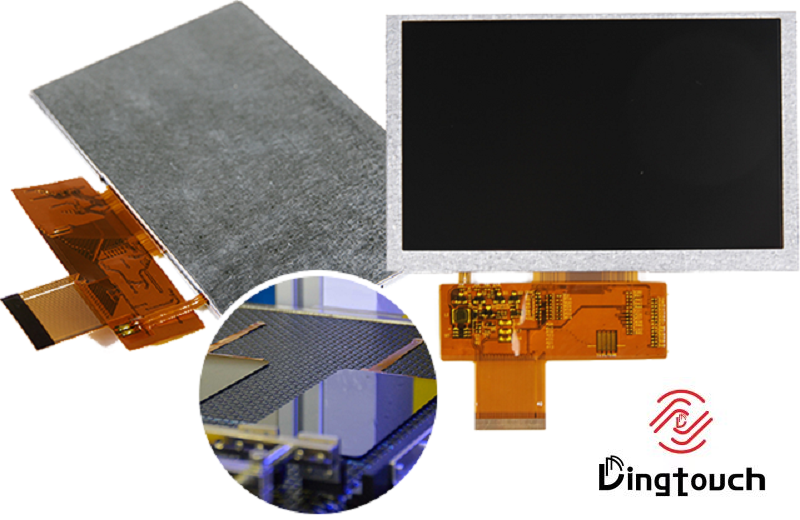

During the manufacturing of touch display modules, film-structure capacitive touch modules (ITO Film Structure) are inherently sensitive to lamination processes due to their material characteristics.

In frame bonding or full OCA lamination, improper process control can easily induce ITO cracking, which is one of the most common yet concealed causes of post-lamination touch malfunction.

Based on extensive failure analysis and mass-production experience, DINGTouch systematically summarizes the failure mechanisms, symptom characteristics, and critical control measures for film-structure touch modules, providing actionable engineering guidance for customers and manufacturing partners.

1. Core Failure Mechanisms of Film-Structure Touch Modules

1.1 ITO–Silver Paste Interconnection Cracking (Critical High-Risk Area)

In film-structure touch modules, ITO sensing patterns are electrically connected to the FPC through silver paste interconnections.

This interconnection area is mechanically fragile. During lamination, OCA removal, cleaning, or disassembly, any of the following may cause micro-cracks:

-

Local compression

-

Bending stress

-

Point pressure

-

Fingernail scratching

Resulting electrical failures include:

-

Excessive contact resistance at the ITO–silver paste joint

-

Entire row or column raw data values significantly reduced

-

Touch lag, channel loss, or complete touch failure

1.2 ITO Damage in the Active Viewing Area

Film-structure touch modules utilize ITO film as the sensing layer, which features good flexibility but poor resistance to compression and abrasion.

ITO damage in the active area is commonly introduced during:

-

Cleaning after full-lamination rework

-

Improper stacking

-

Incorrect handling methods

-

Transportation vibration combined with residual stress

Typical symptoms include:

-

Single-point or localized raw data reduction

-

Partial touch insensitivity

-

Progressive degradation after shipment or field use

2. Inherent Risk Characteristics of Film-Structure Touch Modules

| Item | Risk Description |

|---|---|

| ITO Material | Thin, brittle, extremely sensitive to point pressure |

| Silver Paste Joint | Most critical failure point |

| Rework Capability | Not suitable for secondary reuse |

| Manual Handling | Fingernails, stacking, and improper gripping are high-risk factors |

3. DINGTouch Manufacturing Control Measures (Engineering-Level)

3.1 OCA Removal During Full-Lamination Rework (High Risk)

-

Never initiate OCA peeling from the FPC end or adjacent ITO–silver paste joint areas

-

OCA peeling must start from the non-FPC side

-

Operators must not have fingernails

Purpose: to prevent direct compressive stress on the interconnection area, which would cause excessive contact resistance.

3.2 Reuse Restriction After Full-Lamination Disassembly (High Risk)

-

Film-structure touch modules that have been disassembled after full lamination are not recommended for reuse

-

Cleaning and wiping the back side can easily introduce irreversible ITO cracking

3.3 Handling and Storage Control (High Risk)

-

Operators must not have fingernails

-

Stacking of touch modules is strictly prohibited

-

Proper handling method:

-

✔ Hold the module only by both sides of the cover glass

-

✘ Do not press on the back side

-

Improper handling may cause:

-

Back-side ITO indentation damage

-

Localized raw data reduction

-

Amplified failures after transportation vibration

3.4 OCA Roller Pressure Control During Full Lamination (Medium Risk)

-

Lamination roller pressure and depth must not be excessive

-

Excessive pressure may cause:

-

Interconnection damage

-

OCA overflow

-

Lamination bubbles

-

Establish a clearly defined pressure process window.

3.5 Back Protective Film Design Optimization (High Risk)

-

Recommended: protective film should cover the entire functional touch area

-

Not recommended: protecting only the viewing area

Reason:

-

Partial protection exposes ITO during film removal

-

Peeling may induce compression stress on unprotected ITO

-

Operators must not have fingernails

3.6 ITO Film Thickness Selection for Outsourced Lamination (High Risk)

When film-structure touch modules are sent to LCM manufacturers for full lamination:

-

Dual ultra-thin ITO film structures are not allowed

-

0.05 mm ITO film is not recommended

-

✔ Recommended:

-

ITO film thickness on the lamination side ≥ 0.125 mm

-

Ultra-thin ITO films are highly susceptible to bending damage during downstream processes, resulting in latent touch failures.

3.7 “No-Contact Zone” for ITO–Silver Paste Interconnections (High Risk)

The interconnection area must be strictly avoided during:

-

Housing glue dispensing

-

Film peeling

-

Cleaning

-

OCA removal

Any mechanical interaction in this area may result in:

-

Abnormal contact resistance

-

Channel failure

-

Latent touch malfunctions

4. DINGTouch Engineering Conclusion

The primary risk of film-structure touch modules lies not in design, but in manufacturing discipline and operational details.

Once ITO cracking occurs, touch performance degradation is unavoidable and non-repairable, even if no visual defect is observed.

DINGTouch Engineering Recommendations:

-

Define process limitations at the early project stage

-

Establish strict lamination and rework SOPs

-

Enforce a zero-contact, zero-compression policy for critical interconnection areas

At DINGTouch, we deliver not only touch products, but engineering-ready, mass-production-proven touch display solutions.

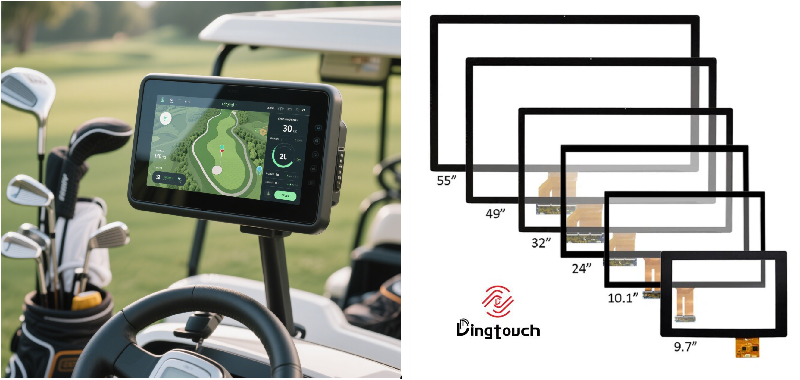

Partner with DINGTouch for Custom Capacitive Touch Solutions

Ready to build your own capacitive touch screen with personalized specifications?

DINGTouch is here to bring your design to life—with precision engineering, premium materials, and industry-leading manufacturing standards.

Email: sales@szdingtouch.com

Email: sales@szdingtouch.com

DINGTouch is here to bring your design to life—with precision engineering, premium materials, and industry-leading manufacturing standards.

Website: www.szdingtouch.com

Website: www.szdingtouch.com

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

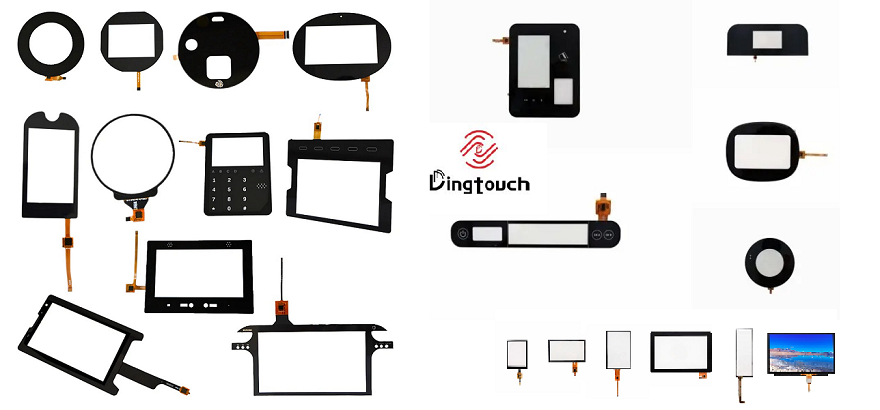

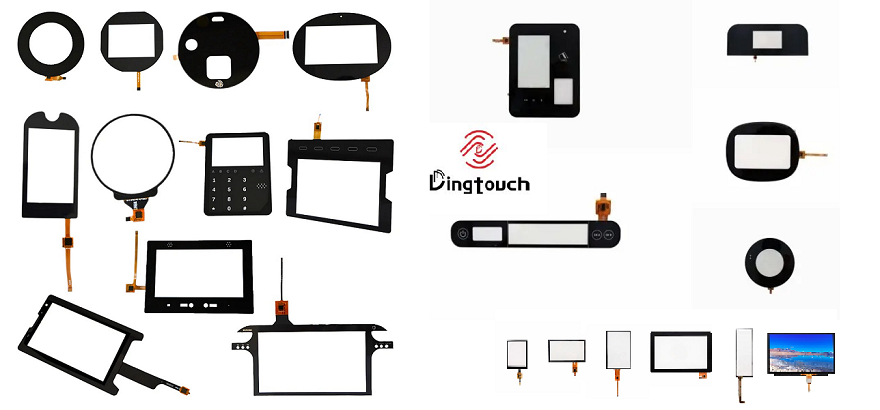

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch