News

Optical Polarizing Film: Structure, Working Principles, and Its Core Role in Modern Display

Optical Polarizing Film: Structure, Working Principles, and Its Core Role in Modern Display

Image quality is one of the most critical performance indicators in TVs, smartphones, automotive dashboards, industrial terminals, and other IT equipment. To achieve clear, high-contrast, and stable image output, the polarizer is an essential optical material.

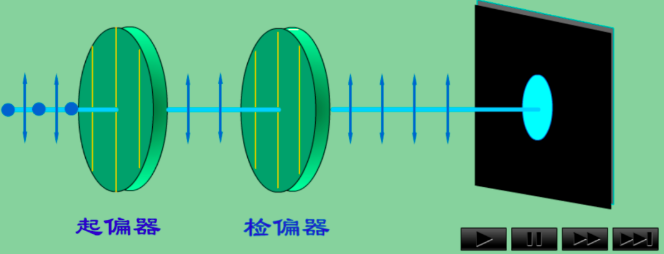

Natural light vibrates randomly in multiple directions. When it passes through a polarizer, only light waves vibrating in one specific direction can pass. This directional filtering effect eliminates stray light and sharpens the image—hence polarizers are often referred to as “optical shutters.”

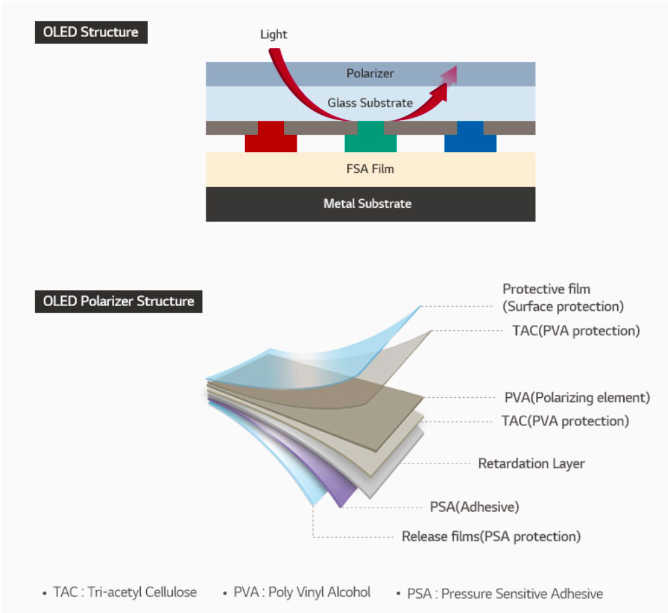

Unlike LCD, which rely on backlight and polarization to control brightness, OLED are self-emissive. However, OLED display may still use polarizing films to improve contrast and reduce reflection.

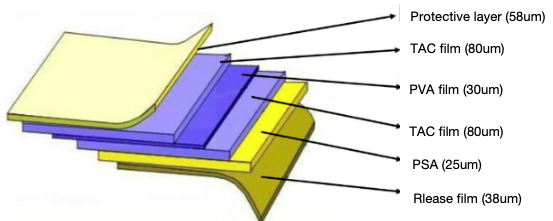

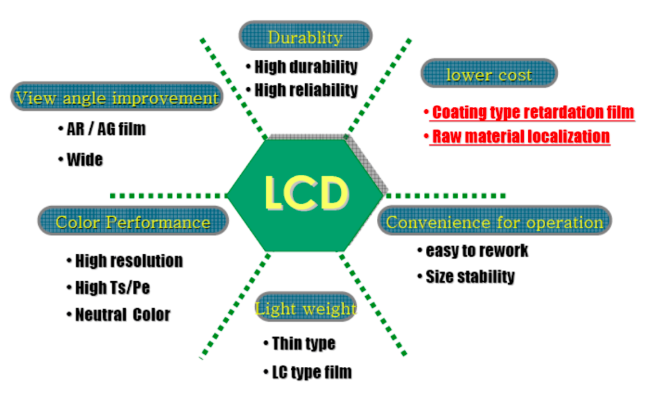

1. Structure of a Polarizer

Modern polarizers are multi-layer optical laminates. Each functional layer works together to achieve high polarization efficiency, optical stability, and environmental durability.

1.1 PVA Polarizing Film (Core Polarizing Layer)

-

Made from polyvinyl alcohol (PVA).

-

Absorbs iodine or organic dichroic dyes to create polarization capability.

-

After stretching, iodine molecules align directionally, forming the absorption axis and transmission axis.

-

Transmission axis is perpendicular to the stretching direction.

1.2 TAC Protective Film

-

Triacetyl cellulose film protects the PVA layer from moisture, heat, and oxidation.

-

Provides scratch resistance and dimensional stability.

-

Essential for long-term reliability.

1.3 PSA Pressure-Sensitive Adhesive

-

Optically clear adhesive for bonding the polarizer to the LCD module.

-

Features high transparency, low haze, and excellent weather resistance.

1.4 Release Film

-

Protects the adhesive layer prior to assembly.

Typical Polarizer Structure

TAC (Protective Layer)

+ PVA (Polarizing Layer)

+ TAC (Protective Layer)

+ PSA (Adhesive)

+ Release Film

2. Working Principles of Polarizers

LCD operation is based on the optical rotation properties of liquid crystals in combination with the directional filtering effect of polarizers.

Optical Operation Process

-

Backlight → Bottom Polarizer

Natural light is converted into linear polarized light. -

Polarized Light → Liquid Crystal Layer

-

No voltage: LC molecules twist the polarization direction by 90° or 270°.

-

Voltage applied: LC molecules stand vertically, no rotation occurs.

-

-

Liquid Crystal Layer → Top Polarizer (Analyzer)

-

If the polarization direction matches the transmission axis → light passes → pixel ON.

-

If it does not match → light is absorbed → pixel OFF.

-

Thus, LCD image formation relies on:

Polarizers determine the “direction” of the light, while liquid crystals determine the “amount” of light passing.

Without Polarizers

-

Light loses directional control.

-

No contrast is formed.

-

The entire display appears blank or emits scattered white light.

3. Types of Polarizers

3.1 By Function

-

Transmissive Polarizer – The most common type for LCD.

-

Reflective Polarizer – Used in reflective displays, e-paper.

-

Transflective Polarizer – For sunlight-readable display.

-

Compensation Polarizer – Reduces color shift and improves viewing angles.

3.2 By Coloring Method

(1) Iodine-based Polarizers

-

High polarization efficiency and high transmittance.

-

Slightly weaker resistance to heat and humidity.

-

Most widely used today.

(2) Dye-based Polarizers

-

Use dichroic organic dyes.

-

Strong environmental resistance, but lower polarization efficiency.

3.3 By Polarizing Material Type

-

Metal Polarizers (obsolete)

-

Iodine Polarizers

-

Dye Polarizers

-

Ethylene Polarizers (structure formed via dehydration reaction)

4. Surface Treatment Technologies

To meet different application requirements, polarizers often incorporate optical coatings:

-

AG (Anti-Glare) – Reduces surface reflection.

-

AG + LR (Low Reflection) – Improves outdoor readability.

-

CHC (Clear Hard Coating) – Enhances scratch resistance, ideal for touch devices.

-

CHC + LR – Widely used on mobile and smart devices.

-

AR (Anti-Reflection) – Boosts contrast and visibility in bright environments.

These coatings are typically applied using wet coating processes, ensuring uniform optical performance.

5. Key Design Considerations for Polarizers

Selecting the right polarizer requires evaluating optical, mechanical, and reliability parameters.

5.1 Optical Performance

-

Transmittance

-

Polarization efficiency

-

Color tone

-

Haze

Critical alignment rules:

-

The absorption axis of the bottom polarizer must be perpendicular to the DBEF film’s transmission axis.

-

For displays using privacy film (light-control film), the orientation must be carefully matched to avoid Moiré patterns.

5.2 Mechanical Performance

-

Warpage

-

Adhesive bonding strength

-

Total thickness and process compatibility

5.3 Reliability

Polarizers must withstand:

6. Future Trends in Polarizer Technology

The rapid evolution of mobile and wearable devices is driving major advancements in polarizer materials and structures.

6.1 Ultra-thin, High-Transmittance Polarizers

Next-generation devices require:

-

Higher brightness

-

Lower power consumption

-

Thinner optical stacks

6.2 In-Cell Polarizer Technology

Integrating the polarizer directly inside the display module offers:

-

Ultra-thin design

-

Higher transmittance

-

Better environmental durability

-

Lower cost

This trend is particularly important for:

-

Flexible OLED

-

Foldable displays

-

Flexible LCD

6.3 Integration with Compensation Films

Combining polarizers and phase-retardation films improves:

-

Viewing angle

-

Color consistency

-

Light-use efficiency

Supporting high-performance displays such as IPS, FFS, Mini-LED LCD.

Conclusion

Polarizers are a fundamental component of modern display technology. Their multilayer structure, precise optical function, and essential role in image formation make them indispensable for achieving high-quality visual performance.

As the industry moves toward ultra-thin, flexible, and energy-efficient displays, polarizer technology will continue evolving—serving as a key driver for next-generation display innovation.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

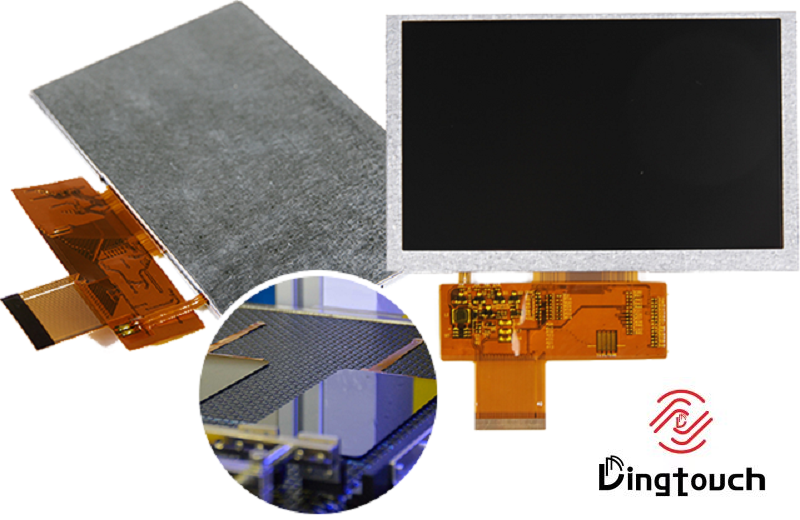

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

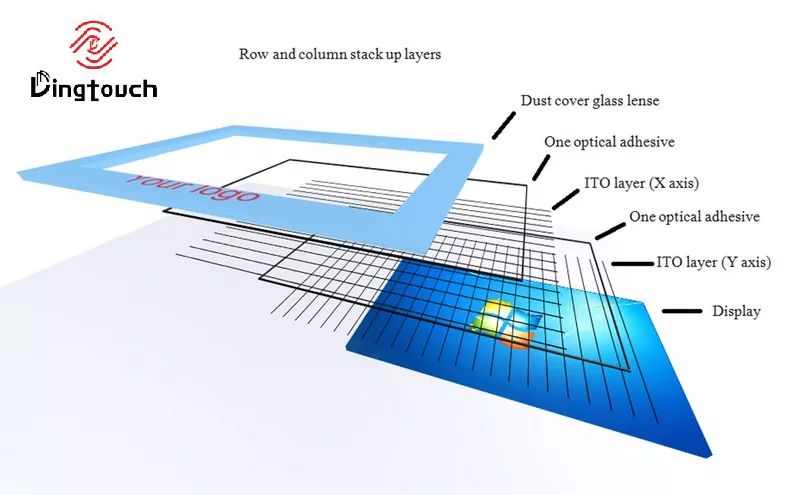

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

#coverglass, #customtouchpanel, #displayglass,#customization

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch