News

High-Precision Pattern Transfer Technology: The Driving Force Behind Capacitive Touchscreen Performance Enhancement

High-Precision Pattern Transfer Technology: The Driving Force Behind Capacitive touchscreen Performance Enhancement

High-Precision Pattern Transfer Technology: The Driving Force Behind Capacitive touchscreen Performance Enhancement

Introduction: The Unsung Hero of the touchscreen Era

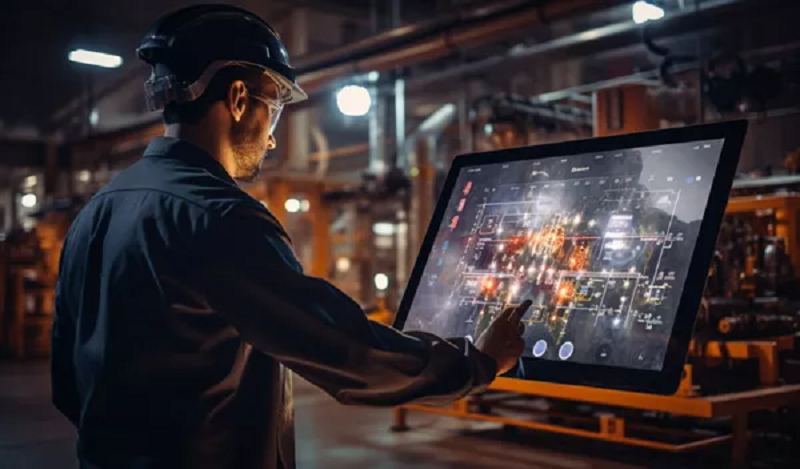

As smart devices continue to evolve, capacitive touchscreens have become the core component of modern human-machine interaction. From smartphones and tablets to industrial control panels and automotive infotainment systems, their performance directly influences user experience. In this context, high-precision pattern transfer technology emerges as a critical manufacturing process that significantly boosts the responsiveness, accuracy, and stability of capacitive touchscreens.

What is High-Precision Pattern Transfer Technology?

High-precision pattern transfer refers to the process of forming micro- or nanoscale conductive electrode patterns on the sensing layer of a touchscreen. These patterns, typically made from ITO (Indium Tin Oxide), metal mesh, or graphene, serve as the “neural network” that captures touch signals. The precision and uniformity of these patterns are essential for touch accuracy, response speed, and long-term durability.

Core Technologies Behind touchscreen Pattern Formation

1. Photolithography – The Mainstream High-Precision Process

Photolithography uses ultraviolet light projected through a photomask onto photoresist-coated conductive layers. After development and etching, intricate electrode structures are formed. This method is ideal for mass production of high-resolution panels, such as those used in smartphones and industrial displays, achieving micro- and even nanoscale precision.

2. Laser Direct Ablation (LDA) – Ideal for Flexibility and Customization

LDA eliminates the need for photomasks by directly etching patterns onto conductive layers using laser beams. This process is suitable for flexible touchscreens and small-batch custom production, offering fast response, maskless operation, and non-contact precision—making it a great solution for metal mesh electrodes and flexible panels.

3. Nanoimprint Lithography (NIL) – High Precision Meets Cost Efficiency

NIL uses a nano-patterned mold to imprint structures directly onto conductive films or substrates, followed by UV or thermal curing. This technology supports large-scale production while maintaining high precision and reducing manufacturing costs, making it suitable for mid-to-large-sized touch displays.

4. Inkjet Printing – A Green and Flexible Manufacturing Approach

Inkjet printing precisely deposits conductive ink onto substrates to form electrode patterns. This method minimizes material waste, increases production flexibility, and supports various base materials such as PET or PI—ideal for flexible OLEDs and wearable devices.

Key Advantages: Elevating the Touch Experience

✅ Higher Touch Accuracy and Sensitivity

Ultra-fine electrode structures enable detection of subtle touch inputs, offering precise control for applications like drawing tablets or medical touch interfaces.

✅ Improved Optical Performance

Uniform, transparent conductive patterns enhance light transmittance and contrast, reducing moiré patterns and color inconsistencies for sharper visual output.

✅ Lower Power Consumption

Efficient electrode designs reduce parasitic capacitance and signal interference, enabling faster signal processing at lower energy usage—ideal for portable or battery-powered devices.

✅ Enhanced Durability and Environmental Resistance

Stable, precisely transferred patterns are more resilient to humidity, temperature fluctuations, and mechanical stress, resulting in longer lifespan and reliable performance in harsh environments.

Future Trends: Enabling the Next Generation of Smart Devices

With the rapid growth of 5G, AIoT, Industry 4.0, and smart healthcare, the demand for advanced touch interfaces is skyrocketing. High-precision pattern transfer technology is becoming a cornerstone of innovation in the capacitive touchscreen industry. Emerging developments include:

-

Higher-resolution, smaller-line-width electrode designs

-

Integration with flexible displays and MicroLEDs

-

Wider adoption of eco-friendly, maskless manufacturing processes

-

Smarter touch systems with AI calibration and self-healing materials

Conclusion: Precision Manufacturing, Exceptional Touch Experience

Though hidden behind the screen, high-precision pattern transfer is a critical enabler of modern touch technology. It's not just a manufacturing breakthrough—it’s the invisible engine powering intuitive, responsive, and energy-efficient interfaces. With ongoing advancements in precision fabrication, the future promises smarter, more versatile, and higher-performing capacitive touchscreens that will serve a wide range of applications—from consumer electronics to industrial automation.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

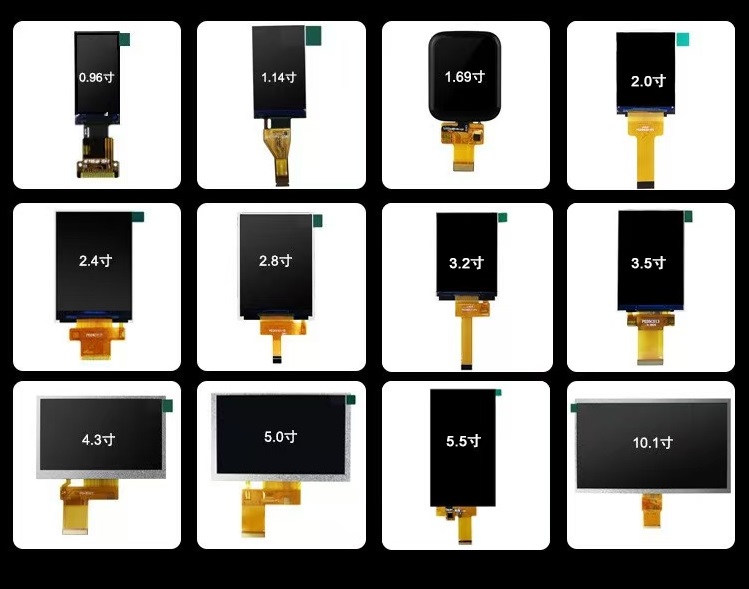

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch