News

Electronic Product Design: From Concept to Prototype

Electronic Product Design: From Concept to Prototype

Electronic product design is both an art and a science—merging creative innovation with precise engineering. Whether developing a smart home panel, an IoT controller, or a custom industrial embedded board, the journey from concept to working prototype follows a systematic path. In this article, we’ll walk through the major stages of electronic product design—from the initial concept to final deployment—illustrated with a real-world example of a Smart Home Control Panel.

1. Start with the Problem – Not the Solution

Successful design begins not with components, but with clarity of purpose. Before choosing a microcontroller or drawing a schematic, identify the core problem your product aims to solve.

Ask yourself (or your client):

- What real-world challenge does this product address?

- Who will use it—and in what environment?

- Which features are essential, and which are optional?

- What’s the desired cost range and production volume?

This problem-definition phase shapes every downstream decision—display size, power architecture, interface types, communication methods, and even the user interface layout.

Pro Tip: Create a user scenario before finalizing specifications. Imagine the end user interacting with your product step-by-step. This approach reveals hidden needs early in the design process.

Case Example: Smart Home Control Panel

Let’s consider designing a Smart Home Control Panel capable of managing a wide range of devices—switches, dimmers, lights, curtains, locks, sensors, and HVAC systems.

Functional Requirements:

- Power Supply: Operates on 220V AC but requires integration of an AC-to-DC converter (110V–240V AC to 5V DC).

-

Form Factor: Fits a standard 86-type wall box, with a modular two-part structure:

- Power Base Box: Installed inside the wall; contains power conversion circuits and terminal connections.

- Front Panel: Mounted externally; houses the 4-inch TFT capacitive touch display and user interface.

- Connectivity: Must support Wi-Fi, Bluetooth, ZigBee, RS485, Ethernet, POE, and relay control.

- Sensors and I/O: Includes a microphone array, speaker, temperature/humidity sensors, ambient light sensor, and distance sensor.

This clear problem definition anchors the project’s next phase—component selection and system architecture.

2. Define the Form Factor and Select Key Components

Once requirements are established, the next step is to define the product’s structure and select the essential components. This phase balances performance, cost, space, and thermal constraints.

Key decisions include:

- Processor/SBC: Choose an SoC or microcontroller offering adequate processing power and I/O (UART, SPI, I2C, GPIO).

- Memory and Storage: Select appropriate DDR and Flash modules.

- Wireless Modules: Ensure antenna placement minimizes interference for Wi-Fi, Bluetooth, and ZigBee.

- Audio Components: Fit a compact microphone array and speaker that meet acoustic needs.

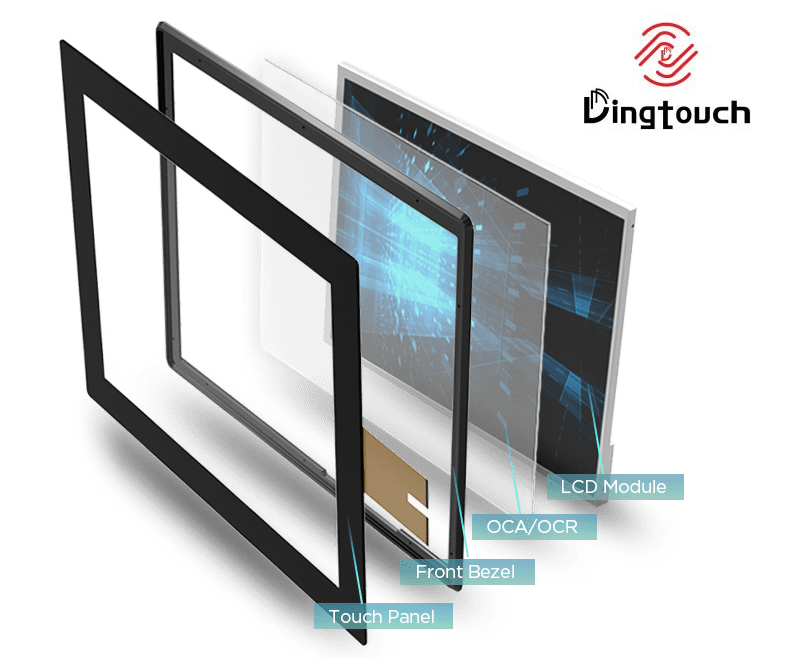

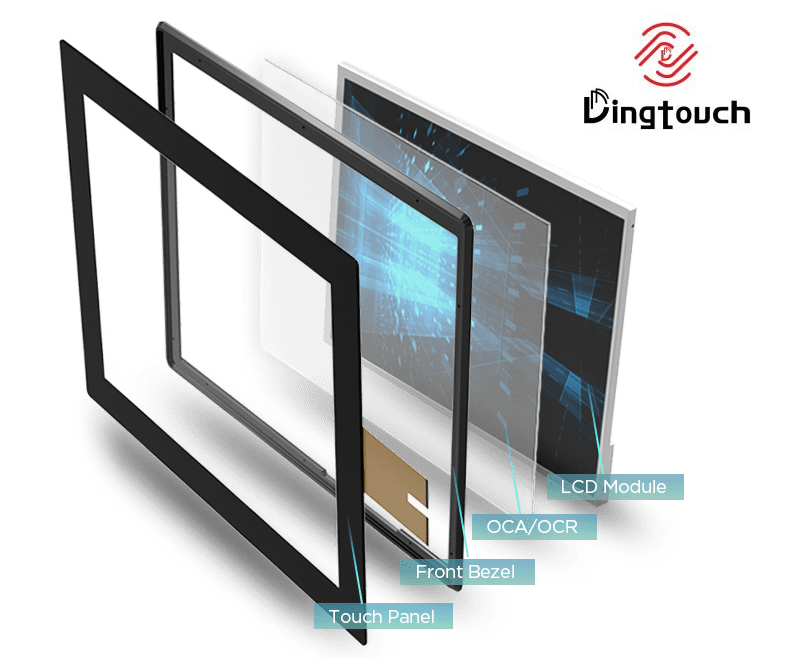

- Display and Touch Panel: Choose a display size, resolution, and capacitive touch technology that enhance usability.

In parallel, mechanical design begins—defining enclosure size, connector placement, sensor windows, and cooling solutions.

Smart Home Example:

During early prototypes, we initially included both POE and environmental sensors. However, to meet the tight 86-box space limitation, non-critical sensors were removed in the final iteration without compromising the user experience.

3. Housing Design, Hardware Prototyping & Firmware Development

With specifications set, we transition from concept to reality. This involves:

- Mechanical Housing Design

- PCB Development

- Firmware Programming

Housing Design and Prototyping

3D CAD tools are used to model the enclosure—ensuring it:

- Aligns perfectly with wall mounting systems

- Provides ventilation and thermal dissipation

- Supports reliable assembly via screws or snap-fit structures

- Balances aesthetic appeal with functionality

Prototyping Methods:

- 3D Printing for rapid iteration

- CNC Machining for accuracy

- Vacuum Casting for small-batch testing

Each prototype undergoes physical fitting, thermal assessment, and usability testing.

SBC Schematic, Layout & Assembly

Once the enclosure is validated, electronic design begins. The schematic includes:

- Power regulation and protection circuits

- Communication interfaces (Wi-Fi, RS485, ZigBee, Ethernet)

- Audio systems and sensors

- Touch display connections

PCB layout focuses on signal integrity, EMI/ESD protection, and compactness to fit within the 86-type enclosure.

After fabrication, engineers assemble and debug the first boards—verifying power sequencing, communication links, and I/O functions.

Firmware Development and System Debugging

Firmware engineers work concurrently on:

- OS porting (Linux or RTOS)

- Peripheral drivers (display, touch, communication modules)

- Protocol stacks (MQTT, ZigBee, Modbus, RS485)

- touchscreen UI development (using Qt, LVGL, or GTK)

- OTA updates and error recovery mechanisms

Hardware and software integration culminates in a fully functional engineering prototype, paving the way for pilot testing.

4. Assembly, Verification, Testing, Tooling, Certification & Launch

With a verified prototype ready, the focus shifts to scaling for production and ensuring reliability.

Assembly and Integration

The assembly process combines all mechanical and electrical components:

- Integrating the power base, SBC, and touch front panel

- Routing internal cables neatly

- Securing parts via screws or clips

- Ensuring uniformity and reliability across multiple units

Functional Verification

Every assembled unit undergoes complete validation:

- Boot and power sequence

- Display and touch performance

- Wireless and wired communication

- Sensor accuracy and audio quality

- Relay switching endurance

Testing and Optimization

Before mass production:

- Aging tests (72-hour burn-in)

- Environmental tests (temperature, humidity, EMI, ESD)

- User experience evaluations

- Field trials for real-world reliability

Results from these tests inform final firmware optimization and assembly refinements.

Tooling and Pilot Production

Once validated:

- Injection molds for enclosures are fabricated

- T1/T2 runs are performed for inspection and refinement

- Surface finishes (painting, texture, logo silk-printing) are applied

- A pilot batch confirms the assembly and QA processes

Product Certification

To meet regional and international compliance standards:

- CE (Europe) – Safety and EMC

- FCC (USA) – Electromagnetic emissions

- RoHS – Material safety

- CCC, SRRC – For the Chinese market

Certification not only ensures regulatory compliance but also builds customer trust—especially for global B2B clients.

Product Launch

At this point, the product is ready for commercialization:

- Final firmware version locked

- Packaging, manuals, and branding completed

- Production line optimized

- Marketing and distribution launched

The Smart Home Control Panel now transitions from concept to a real-world, deployable product—marking the successful completion of the electronic product design journey.

DINGTouch: Turning Innovation into Reality

At DINGTouch, we specialize in helping clients bring their electronic product ideas to life—offering:

- Customized Touch Display Solutions (sizes from 2.8” to 65”)

- G+G and G+F+F Touch Structures

- High-brightness, multi-touch, and ruggedized designs

- Custom interfaces (I2C, USB, SPI, RS485, UART, etc.)

- Personalized and differentiated design support

With years of experience and numerous successful cases in industrial, smart home, medical, commercial, and automotive applications, DINGTouch provides tailored solutions that perfectly match each client’s product vision.

If your next project requires a specialized or custom touch screen, contact the DINGTouch technical team at

![]() sales@szdingtouch.com

sales@szdingtouch.com

Bring your concept to life—from idea to prototype—with DINGTouch.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch