News

Analysis of Mura Phenomenon in Full-Laminated Displays and Optimization of OCA Mechanical Properties

Analysis of Mura Phenomenon in Full-Laminated Displays and Optimization of OCA Mechanical Properties

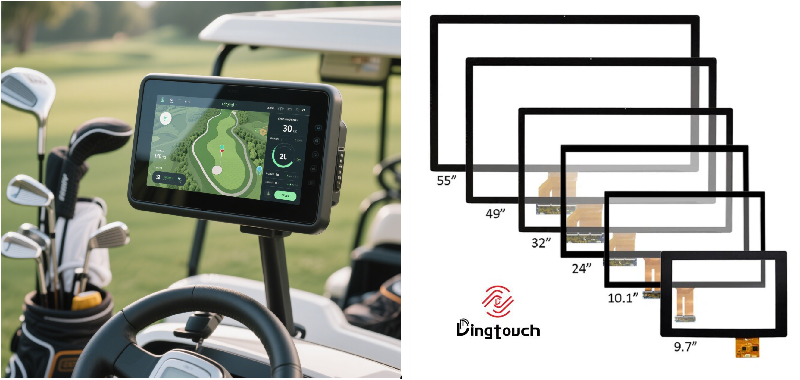

A Material-Mechanics-Based Custom touchscreen Solution

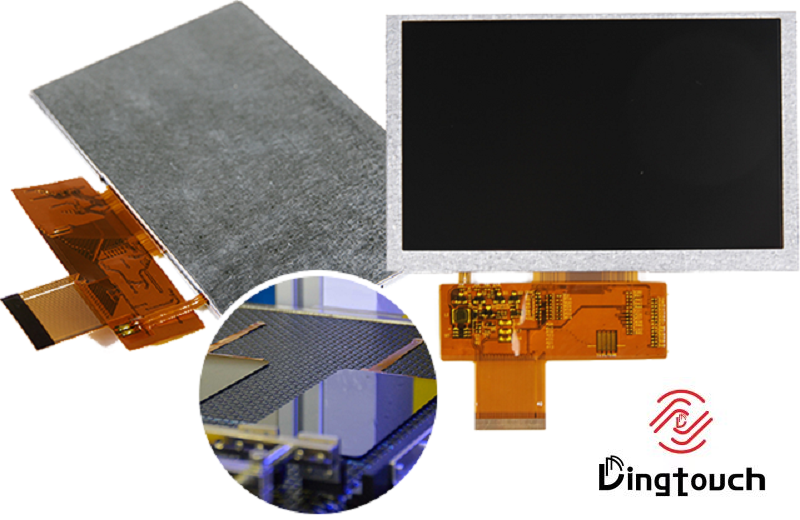

During the full lamination process of touch display, the Mura phenomenon (display non-uniformity) is one of the most common and challenging appearance defects.

It typically appears under low gray-level images, presenting as localized brightness variations, yellowish stains, or stripe-like patterns, which significantly affect visual performance and perceived product quality.

As a professional custom touchscreen and display solution provider, DINGTouch analyzes the root causes of Mura from a material mechanics and process engineering perspective, focusing on the critical role of OCA (Optical Clear Adhesive). This article provides practical optimization strategies to help customers reduce Mura risks at the early design stage.

1. What Is Mura in Full-Laminated Display?

Mura is not a single defect but a comprehensive optical phenomenon caused by micro-level structural and stress non-uniformities within the display module.

Typical Characteristics of Mura

-

Visible under low gray-scale or dark display conditions

-

Appears as bright spots, dark areas, yellow stains, or cloud-like patterns

-

Often develops days after lamination or during aging tests

Core Cause: Stress-Induced Cell Gap Variation

In a fully laminated module, the LCD cell gap is extremely sensitive to mechanical stress.

When stress is unevenly transferred to the LCD glass, micro-level deformation occurs, resulting in uneven light transmittance, which becomes visible as Mura.

2. Stress Sources in the Full Lamination Process

In many practical cases, Mura is closely related to OCA material properties and lamination processes, rather than inherent LCD defects.

Common Observations in Engineering Projects

-

Display looks normal immediately after lamination

-

Mura appears after several days of storage or aging

-

Mura disappears once the CTP (cover glass + touch panel) is removed

-

Mura reappears after re-lamination

These phenomena clearly indicate that OCA-induced stress is the key factor.

3. Impact of OCA Mechanical Properties on Mura

3. Impact of OCA Mechanical Properties on Mura

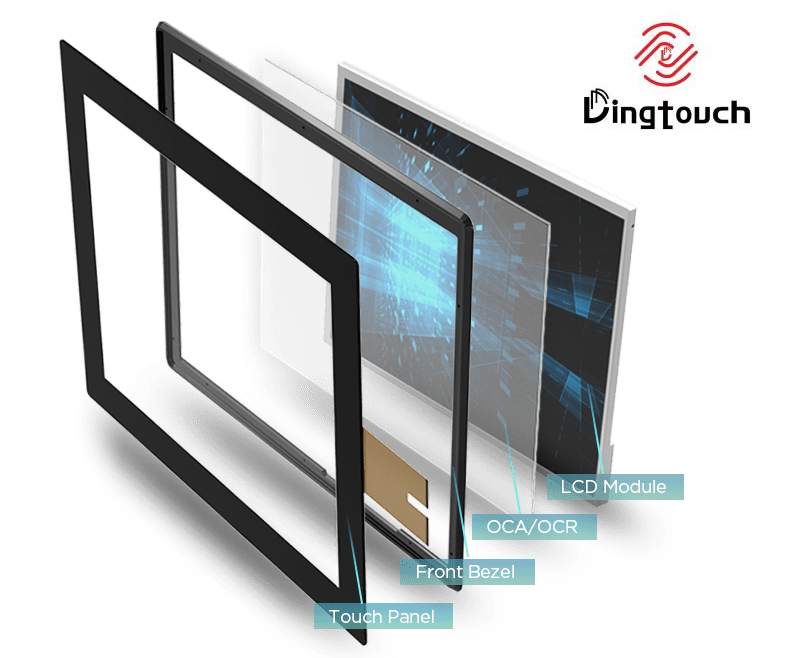

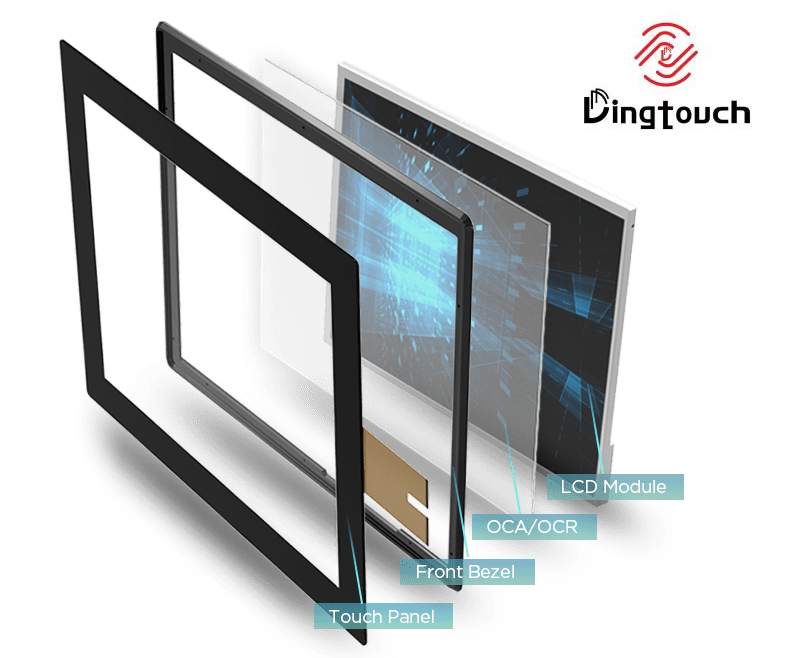

OCA is not just a bonding layer—it is a critical stress-buffering component in the display stack. Its mechanical behavior directly affects stress distribution and display stability.

3.1 Elastic Modulus

-

High elastic modulus (hard OCA):

-

Poor strain absorption

-

Easily transfers external deformation to the LCD

-

-

Low elastic modulus (soft OCA):

-

Excellent stress-buffering capability

-

Reduces stress concentration on the liquid crystal layer

-

Recommendation:

For industrial, medical, or high-reliability displays, low-modulus OCA should be prioritized based on mechanical testing data.

3.2 OCA Thickness

OCA thickness is positively correlated with stress absorption capacity:

-

Thin OCA layers (≤175 μm):

-

Limited stress relief

-

More sensitive to glass warpage and temperature changes

-

-

Thicker OCA layers (≥200 μm):

-

Improved stress distribution

-

Lower Mura risk

-

Recommendation:

Increase OCA thickness within structural constraints to significantly enhance display uniformity.

3.3 OCA Structural Design

Some advanced OCA materials adopt a multi-layer or sandwich structure, combining:

-

High thickness

-

Low elastic modulus

This design allows stress to be distributed more evenly across the module and has demonstrated more stable optical performance and lower Mura occurrence in testing.

3.4 Curing Behavior and Shrinkage Control

OCA or OCR shrinkage during curing is another critical source of internal stress:

-

Rapid UV curing may lock in residual stress

-

High shrinkage materials increase long-term Mura risk

Process Optimization Strategies:

-

Select low-shrinkage OCA materials

-

Use step-by-step UV curing

-

Apply low-temperature, slow curing processes

These methods effectively reduce internal stress accumulation.

4. DINGTouch Custom Full-Lamination Solutions

With extensive experience in touchscreen and display lamination projects, DINGTouch offers a systematic approach to Mura control:

✔ Material-Level Customization

-

Multiple OCA/OCR options with different moduli and thicknesses

-

Mechanical and optical performance evaluation

✔ Structural Optimization

-

Coordinated design of cover glass thickness and OCA thickness

-

Support for large-size, narrow-bezel, and IK-rated displays

✔ Process Validation

-

Lamination process verification before mass production

-

Low-gray display, aging, and thermal stress testing

✔ Project-Oriented Engineering Support

-

Early involvement to reduce development risks

-

Ideal for industrial control, medical devices, energy systems, kiosks, and outdoor applications

5. Conclusion: Mura Is an Engineering Variable—Not a Matter of Chance

Mura in fully laminated displays is the result of material mechanics, structural design, and process control.

By optimizing OCA mechanical properties and implementing customized lamination strategies, Mura risks can be effectively controlled at the design stage.

If your project involves:

-

Full-laminated touch displays with high reliability requirements

-

Large-size or industrial-grade applications

-

Long-term display uniformity concerns

DINGTouch is ready to provide custom touchscreen and full-lamination solutions tailored to your needs.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

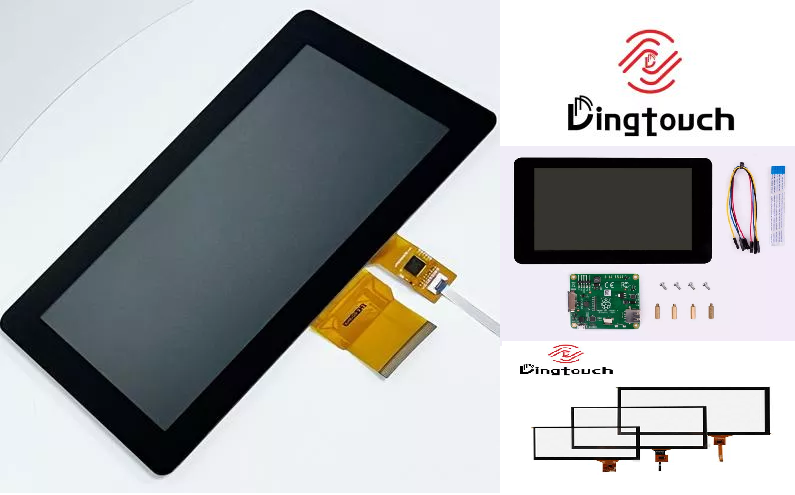

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

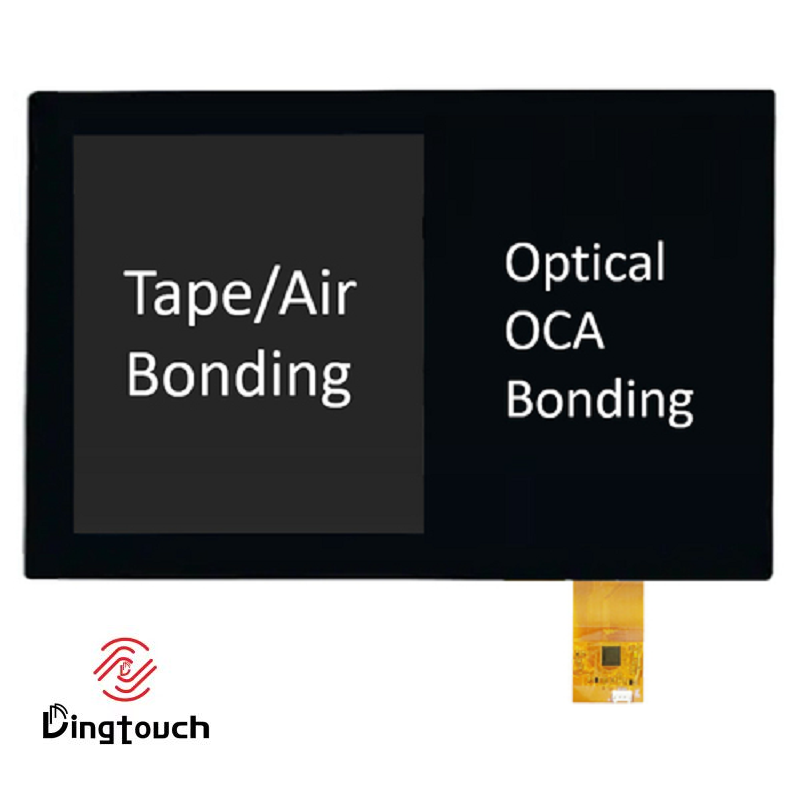

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

![]() Email: sales@szdingtouch.com

Email: sales@szdingtouch.com

![]() Website: www.szdingtouch.com

Website: www.szdingtouch.com

What DINGTOUCH can do:

Dingtouch Industrial Capacitive Touch Screen Manufacturer

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch