News

Air Bonding vs. Optical Bonding: How to Choose the Best Solution for Your Display Project

Air Bonding vs. Optical Bonding: How to Choose the Best Solution for Your Display Project

Air Bonding vs. Optical Bonding: How to Choose the Best Solution for Your Display Project

In industrial LCD systems, medical monitors, and automotive control panels, the bonding method between the LCD panel and the cover glass is a critical design choice that directly impacts display quality. The selected bonding technique influences visual clarity, durability, sunlight readability, shock resistance, and moisture protection—all of which determine long-term performance.

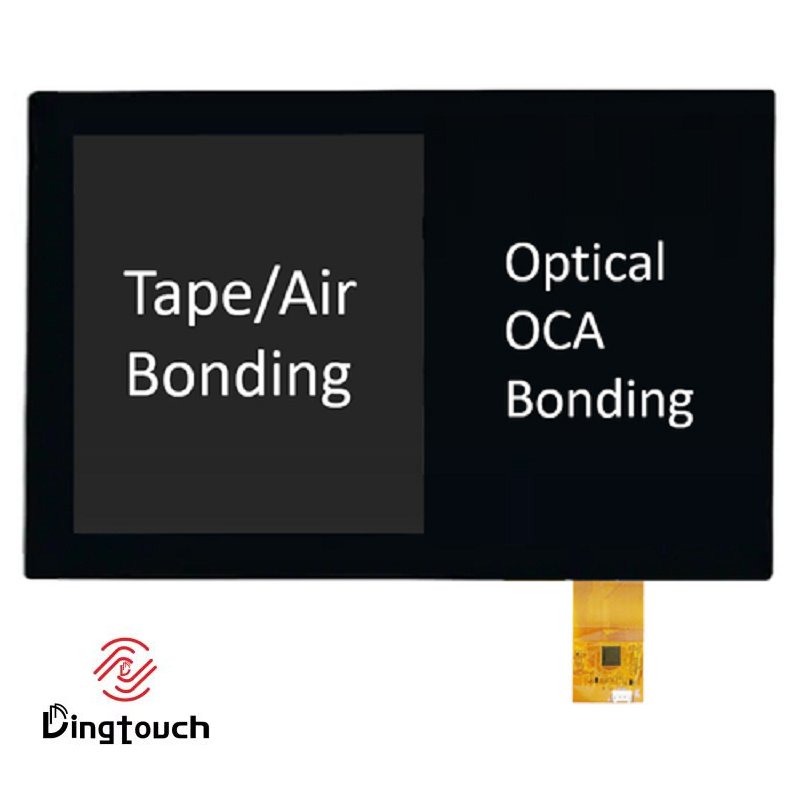

Currently, the two most common display bonding techniques are air bonding and optical bonding. Each has unique advantages and ideal use cases. Engineers and product designers must carefully evaluate their project requirements to ensure optimal results.

What Is Air Bonding?

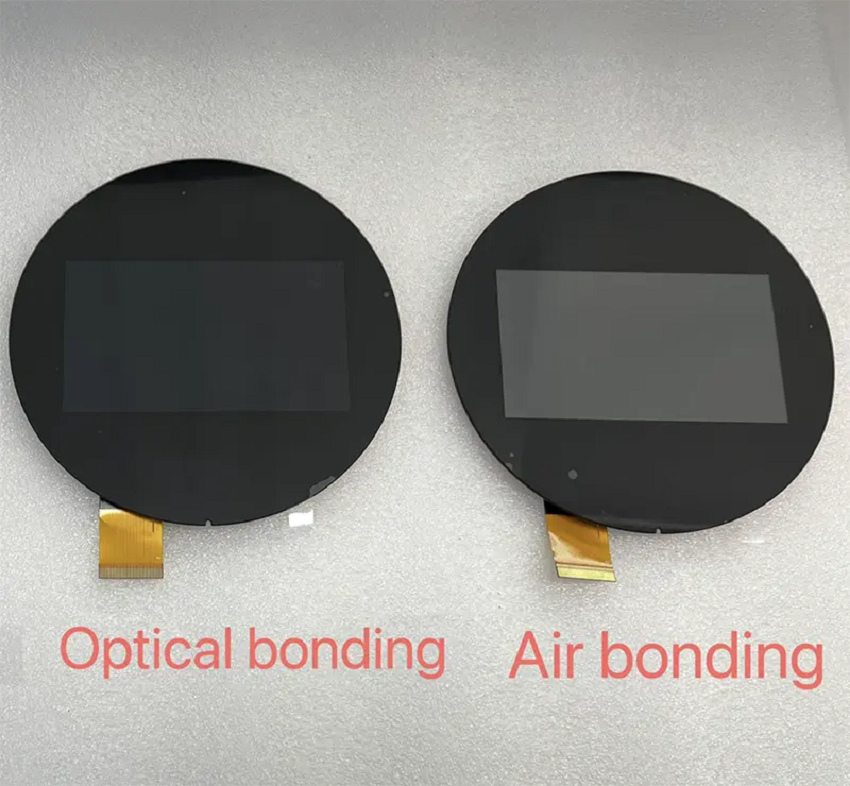

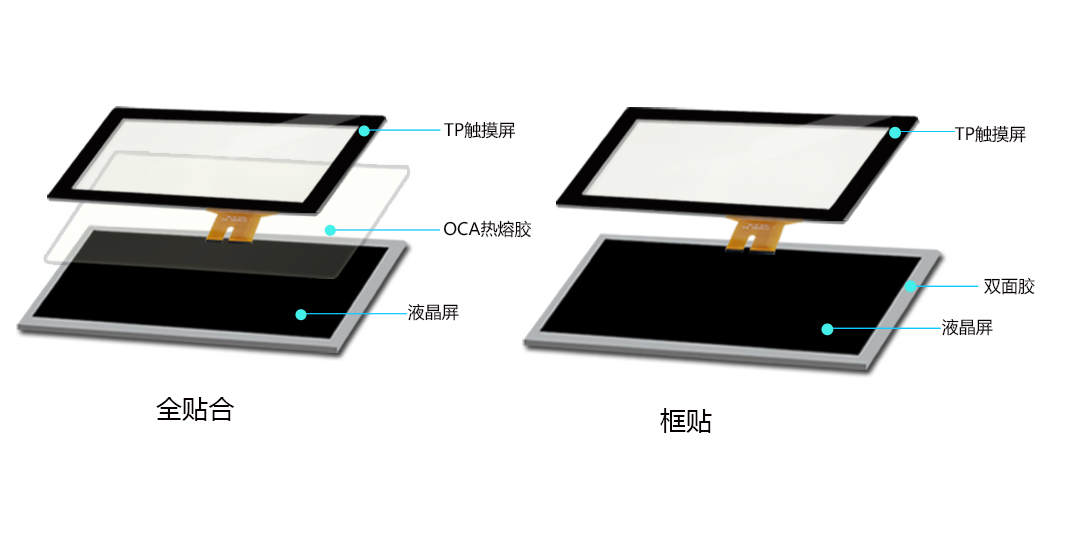

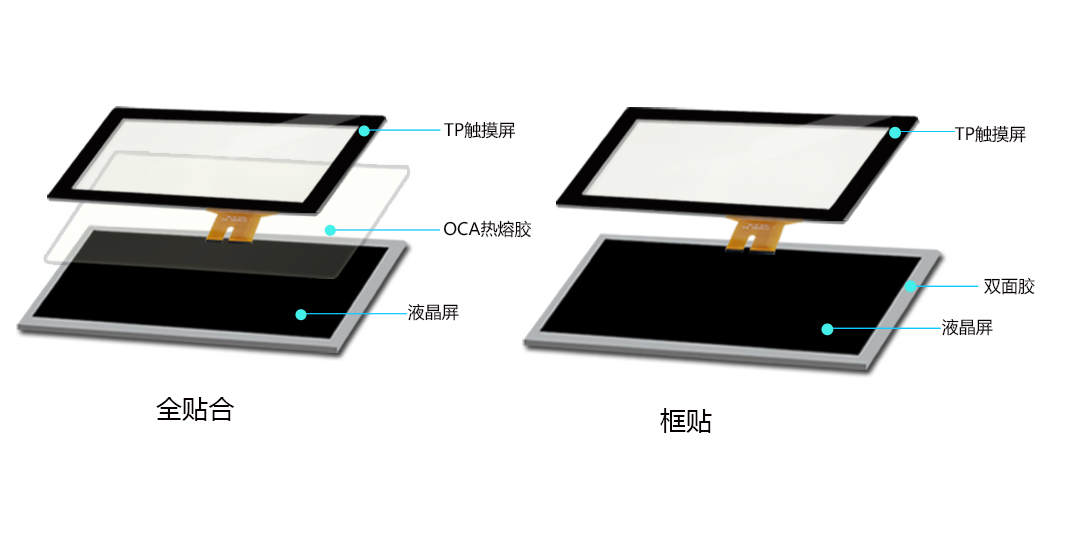

Air bonding—also called perimeter bonding—applies adhesive only around the edges of the cover glass or touchscreen, leaving a thin layer of air between the LCD and the glass.

This approach is widely used in cost-sensitive consumer electronics thanks to its simplicity and lower manufacturing cost. You’ll find it in devices such as indoor touch monitors, consumer tablets, and smart-home control panels.

However, the air gap introduces several optical and reliability issues:

-

Internal reflections and glare that reduce sunlight readability

-

Dust and moisture intrusion over time, compromising long-term stability

Key Benefits of Air Bonding

-

Lowest production cost—ideal for budget-sensitive projects

-

Easier assembly and maintenance

-

Adequate for indoor environments with controlled lighting

What Is Optical Bonding?

Optical bonding is a full lamination process that uses an optically clear adhesive (OCA) or optically clear resin (OCR) to eliminate the air gap entirely, bonding the LCD panel and cover glass into a single optical unit.

By removing internal reflections and sealing the layers, optical bonding delivers major performance gains:

-

Superior sunlight readability and higher contrast ratios

-

Enhanced durability, including resistance to shock, vibration, and temperature changes

-

Excellent protection against dust and moisture—critical for IP-rated industrial displays

-

Improved touch accuracy with reduced parallax, essential for precise HMI and medical interfaces

Key Benefits of Optical Bonding

-

Outstanding outdoor readability with minimal glare

-

Higher structural strength and impact resistance

-

Exceptional moisture and dust resistance

-

More accurate touch response for projected-capacitive (PCAP) screens

-

Longer service life with lower maintenance costs

Side-by-Side Comparison: Air vs. Optical Bonding

Side-by-Side Comparison: Air vs. Optical Bonding

| Feature | Air Bonding | Optical Bonding |

|---|---|---|

| Visual Clarity | Moderate; prone to reflections | Excellent; no internal reflections |

| Durability | Lower | High shock & vibration resistance |

| Sunlight Readability | Poor | Superior |

| Moisture Resistance | Limited | Excellent |

| Manufacturing Cost | Low | Higher |

| Typical Applications | Consumer electronics, indoor devices | Industrial, medical, outdoor, ruggedized |

For industrial and embedded displays, where humidity, vibration, and outdoor brightness are factors, optical bonding delivers long-term performance and reliability that air bonding cannot match.

Choosing the Right Method

-

Cost-Driven Products

If your product is strictly budget-oriented and intended for controlled indoor environments—such as consumer tablets or basic smart-home panels—air bonding is a practical, economical option. -

Demanding Industrial or Outdoor Applications

For devices requiring outdoor visibility, moisture resistance, and mechanical strength—including industrial HMIs, medical monitors, automotive dashboards, and outdoor kiosks—optical bonding is the superior choice.

In high-humidity or dusty environments, optical bonding reduces maintenance needs and extends product life, providing a higher return on investment despite the higher upfront cost.

Industries and Applications Where Optical Bonding Excels

Optical bonding’s durability and optical performance make it indispensable in:

-

Medical equipment: surgical monitors and diagnostic displays requiring crystal-clear images and hygienic surfaces

-

Industrial HMI panels: factory automation and process-control displays operating 24/7

-

Military and law-enforcement rugged tablets: devices exposed to extreme weather, vibration, and shock

-

Premium smart-home interfaces: touch panels for high-end lighting, HVAC, and security control

-

Outdoor digital signage and kiosks: public transport displays, smart-city panels, and other high-brightness applications

Future Trends and Manufacturing Advancements

As display technology evolves, optical bonding continues to improve:

-

Higher production yields with fewer defects and lower waste

-

Advanced adhesive materials enabling thinner designs and higher brightness without sacrificing optical quality

-

Integration with AI and IoT driving demand for modular, customized bonded displays tailored to smart devices

These advancements are expanding optical bonding into new markets, from wearables to intelligent infrastructure.

Conclusion: Balancing Cost, Performance, and Longevity

Both bonding methods have their place:

-

Air bonding is the economical solution for cost-sensitive, indoor consumer products.

-

Optical bonding provides unmatched readability, durability, and reliability for industrial, medical, and outdoor systems.

For mission-critical embedded systems, the long-term benefits of optical bonding outweigh its higher initial cost, offering improved user experience and reduced maintenance over time.

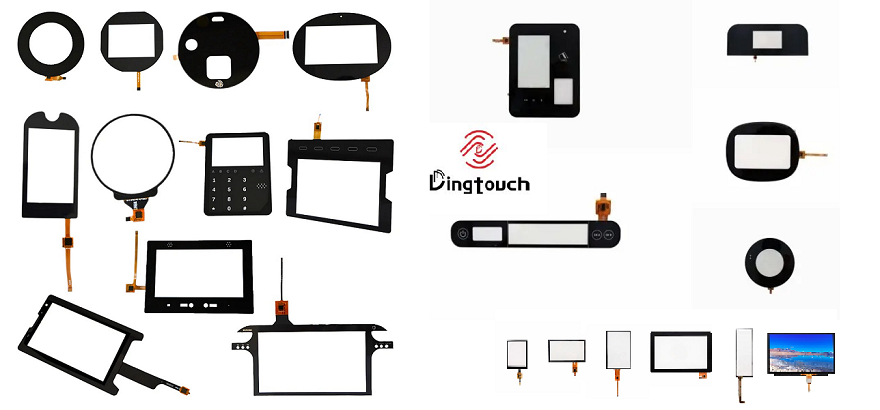

If your project requires optical bonding, consult an experienced display manufacturer for technical guidance and customization. DINGTouch offers high-performance HMI and touchscreen solutions with advanced optical bonding options, helping your products excel in demanding industrial and outdoor environments.

Frequently Asked Questions

1. What’s the difference between air bonding and optical bonding?

Air bonding leaves an air gap between the LCD and cover glass, while optical bonding uses optically clear adhesive to eliminate that gap, improving brightness, readability, and durability.

2. Why choose optical bonding for industrial LCD?

It enhances outdoor visibility, increases shock and vibration resistance, and protects against dust and moisture—ideal for industrial, medical, and rugged applications.

3. Does optical bonding improve touch performance?

Yes. By removing the air gap, optical bonding eliminates parallax and provides more precise touch response, especially on PCAP touchscreens.

4. What adhesives are used in optical bonding?

Typically optically clear adhesive (OCA film) or optically clear resin (OCR liquid), both offering high transparency and stability.

5. Is optical bonding more expensive?

Yes, but its benefits—greater reliability, longer lifespan, and lower failure rates—deliver significant long-term value for critical applications.

By understanding the differences between air bonding and optical bonding, you can make the best decision for your display project, balancing cost considerations with the performance and durability your application demands.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedical display, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions, #Waterproof Touchscreen

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

DINGTouch delivers more than a screen—we provide end-to-end design, engineering, and customization to help your industrial applications thrive.

What DINGTOUCH can do:

Dingtouch Industrial Capacitive Touch Screen Manufacturer

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch