News

What are the sturdy panel materials for touch screens?

What are the sturdy panel materials for touch screens?

Regarding what sturdy panel materials are available for touchscreens: Here are some common sturdy touchscreen panel materials:

1. Toughened Glass: Toughened glass is a specially treated glass material with stronger impact resistance and scratch resistance. It is heated and quenched to create compressive stress on its surface, improving the strength and durability of the glass.

2. Polycarbonate: Polycarbonate is a strong plastic material with high impact resistance and durability. It is commonly used in touch screen applications that require a high degree of ruggedness and durability.

3. Tempered Film: Tempered film is a polymer-based protective film with strength and impact resistance similar to tempered glass. It provides extra protection on the touch screen surface from scratches, scuffs and chips.

4. Scratch-resistant glass: Scratch-resistant glass is a specially coated glass that has high scratch resistance. This type of glass is often used to protect screens from scratches and smudges.

5. Polymer Film: Polymer film is a soft and strong material, usually used for touch screen protective films. While it may not be as strong as tempered glass, it offers a degree of scratch and impact resistance.

Please note that different touch screen manufacturers and devices may use different panel materials. Depending on the device you're using and when it comes to solid panels for touch screens, here are some common options:

Tempered Glass: Tempered glass is a specially treated glass material with high impact and scratch resistance, which can effectively protect the touch screen from damage. It is widely used in touch screen protection for mobile phones, tablets and other electronic devices.

Polycarbonate or PC: Polycarbonate is a strong plastic material with high durability and impact resistance. It can be used as a protective panel for touch screens, providing effective screen protection.

High-Strength Glass Fiber: High-strength glass fiber is a strong panel made of fiberglass and resin composite materials. It offers exceptional strength and durability to provide protection in the toughest conditions.

Alumina: Alumina is a ceramic material with very high hardness and mechanical strength. It is used in industry and aerospace to make durable touch screen panels.

Sapphire: Sapphire is a very hard gem material with excellent scratch resistance. It is used in screen protection on some high-end phones and watches.

These are common materials for rugged touch screen panels, each with different advantages and characteristics in different applications. Which material you choose depends on your specific needs, budget, and application. Common rugged panel materials for touch screens include:

Tempered Glass: Tempered glass is a special heat-treated glass with high strength and impact resistance. It effectively resists damage from scratches and drops and is widely used in touch screens for smartphones, tablets and other electronic devices.

Silicone: Silicone is a soft yet durable material with excellent shock-absorbing and shock-resistant capabilities. It is commonly used in industrial equipment and touch screens that require additional protection in some special environments.

High-strength Engineering Plastic: High-strength engineering plastics such as polycarbonate (PC) or polyimide (PI) have high hardness and wear resistance. They are commonly used in touch screens that require rugged protection, such as automotive navigation systems, industrial control equipment, and outdoor kiosks.

Explosion-proof Film: Explosion-proof film is a special film coating that can effectively prevent the screen from bursting due to impact. It is commonly used in industrial and commercial situations that require high levels of safety and protection.

Polymer composites: Polymer composites are composite materials that combine multiple materials and have excellent physical and mechanical properties. They are commonly used in fields such as military equipment, aerospace, and industrial automation that require high touch screen ruggedness.

These strong panel materials play an important role in protecting the touch screen from damage. Which panel material to choose? Rugged panels for touch screens usually use some special materials and technologies to provide better durability and protection. Here are some common solid panel materials:

Tempered Glass: Tempered glass is a specially treated glass with high impact resistance and scratch resistance. It is commonly used in protective panels for cell phones, tablets and other touch screen devices.

Polycarbonate (PC): Polycarbonate is a rigid plastic material that offers good durability, impact resistance, and scratch resistance. It is often used for touch screen panel protection in industrial and commercial applications.

Explosion-proof film: Explosion-proof film is a specially designed protective film that can prevent the screen from exploding and shattering. It is usually highly impact-resistant and shatterproof.

Silicone Case: In some cases, the touch screen may be equipped with a silicone case, a soft material that can effectively protect the screen from damage due to falls or collisions.

Anti-fingerprint Coating: Some touch screen panels are equipped with anti-fingerprint coating to reduce fingerprints and smudges and keep the screen clear.

Waterproof and dustproof design: Some touch screen panels are waterproof and dustproof to protect the screen from liquids and particles.

Other Special Coatings: Some touch screens may have other special coatings applied, such as anti-scratch coatings or anti-peeping films, to enhance the durability and performance of the panel.

The selection of these materials and technologies depends on the application scenarios and needs of the touch screen. For example, if used in an industrial environment, stronger impact resistance and protection may be required, whereas in general consumer electronics equipment, scratch resistance and fingerprint protection may be more important.

What DINGTOUCH can do:

• PCAP maximum size 65”• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

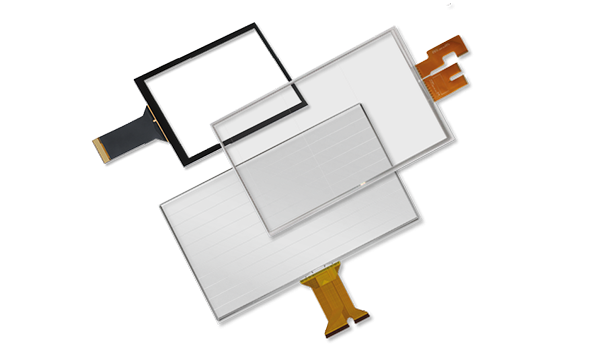

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch