News

Water Glue Full Laminating Process-Touch Screen Lamination New Era

Water Glue Full Laminating Process-Touch Screen Lamination New Era

With the full bonding process becoming the basic configuration of capacitive touch screen bonding. At present, the mainstream mid-to-high-end touch screen and display module combination technology on the market adopts a full bonding process. Most manufacturers use the OCA full bonding method. But because this method is only suitable for small and medium size bonding. it can no longer fully meet the requirements of industry development. Therefore,water glue full laminating process-touch screen lamination new era.

Advantages Of Water Glue Full Lamination

Faced with many bottlenecks encountered in OCA full bonding process. One of the solutions is to develop a new bonding process to meet market demand. At this time, the advantages of water glue full bonding are gradually becoming prominent. It has the characteristics of high light transmittance, low cost, wide use size and high yield. Especially for the full lamination of medium and large sizes. It has obvious cost and process advantages. So it is precisely based on these that the industry has anticipated that in the future medium and large-size fully-laminated products will be the mainstream trend of water-adhesive fully-laminated technology!

Three Problems The Water Glue Full Lamination For Touch Screen Lamination:

Difficult Problem With Spilled Glue

Liquid fluid needs to control its flow direction and the specific shape and size formed after leveling. This has always been a technical problem. Therefore,Dingtouch successfully integrated the common advantages of "Slit Coating Technology" and "Jelly Water Glue Technology". The problem of glue overflow in the water glue is well solved.

Thickness And Difficult Questions

Controlling the thickness of liquid objects formed after flowing is also one of the difficulties. The thickness control that can be achieved by self-leveling + time control also has certain limitations. However, based on years of research, Dingtouch builds the coating components and automatic height compensation system based on the marble platform. The flatness of the adjustment is high, which can effectively control the thickness uniformity of the glue coating.

Bubble Problem:

As a liquid object, glue has a certain degree of gas solubility. In other words, the glue contains a certain amount of gas in it. Stirring, the flow is prone to gas gathering to form bubbles. Dingtouch According to the characteristics of water glue. Adopt the vacuum chamber to complete the full bonding, with less bubbles, low pressure, and easy defoaming behind the large-scale and high-yield rate is the process, and behind the process is the equipment. We concentrate on the research and development of new technologies. So we hope to provide sustainable and effective support to customers! In the future, we will continue to innovate and continue to integrate high-quality resources. Make unremitting efforts to create better user value!

Dingtouch Smart Touch Screens Manufacturer

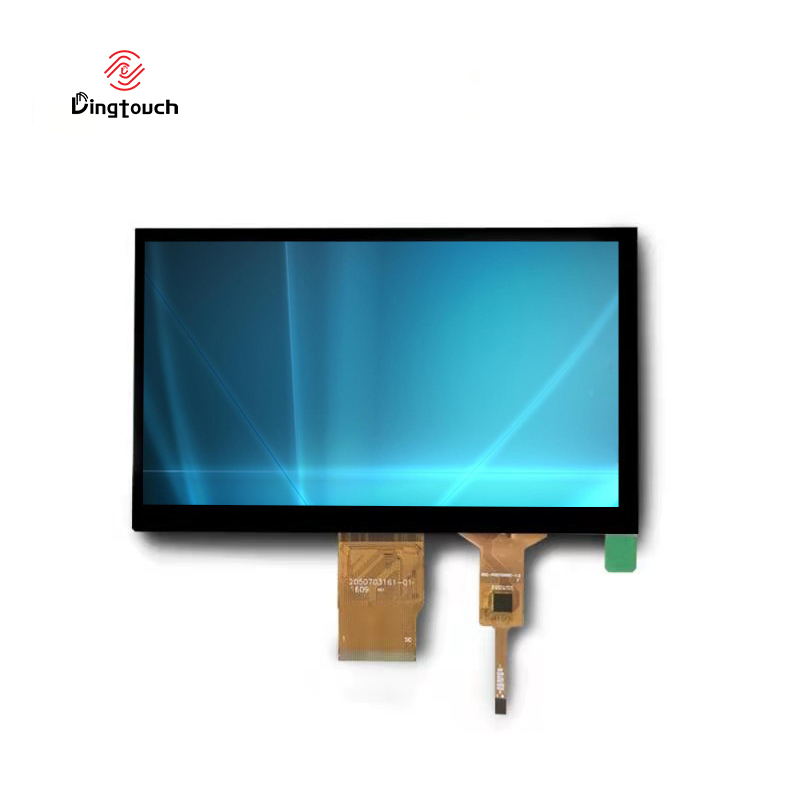

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen .Such as 5 inch touch screen, 7 inch touch screen,10.1 inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen , 32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to lean what capacitive touch screen are best for our retail business needs. Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch