News

AMOLED Display Technology Explained

AMOLED Display Technology Explained

Core Architecture, Key Innovations, and the Future of Self-Emissive Displays

As display performance becomes a defining factor in modern electronic products, AMOLED (Active Matrix Organic Light-Emitting Diode) technology has emerged as a leading solution for high-end visual applications. With its self-emissive pixels, ultra-high contrast ratio, fast response time, and flexible form factors, AMOLED is widely adopted in smartwatches, wearable devices, premium consumer electronics, and customized display solutions.

This article explores the core architecture of AMOLED display, the key technological innovations driving performance and efficiency, and the future direction of advanced display technologies.

What Makes AMOLED Display Technology Unique?

What Makes AMOLED Display Technology Unique?

Unlike traditional LCD that rely on a backlight module, AMOLED display feature self-emitting pixels, where each pixel generates its own light. When displaying black, pixels are completely turned off, resulting in near-zero power consumption and true black levels.

Key advantages of AMOLED display include:

-

Ultra-high contrast ratio with deep, true blacks

-

Fast response time, ideal for dynamic content and wearables

-

Wide color gamut and high color saturation

-

Slim, lightweight, and flexible design options

-

Excellent viewing angles with minimal color shift

Structurally, an AMOLED display consists of three critical layers:

-

TFT Backplane (Driving Layer)

-

OLED Emissive Layer

-

Thin-Film Encapsulation (TFE)

Among these, the TFT backplane technology plays a decisive role in display performance, power efficiency, and long-term stability.

Why Do Modern AMOLED Displays Use LTPS or Oxide Backplanes?

Why Do Modern AMOLED Displays Use LTPS or Oxide Backplanes?

Early AMOLED panels were driven by amorphous silicon (a-Si:H) TFTs, which suffered from low carrier mobility and poor stability, making them unsuitable for precise OLED current control.

Today, the industry primarily relies on two advanced backplane technologies:

LTPS (Low-Temperature Polycrystalline Silicon) TFT

-

High carrier mobility

-

Enables high resolution and high pixel density (PPI)

-

Ideal for small and medium-sized AMOLED displays

Oxide TFT (e.g., IGZO)

-

Ultra-low leakage current

-

Excellent pixel retention and power efficiency

-

Well-suited for static or low-refresh-rate display scenarios

These backplane technologies enable AMOLED panels to deliver superior brightness control, color accuracy, and reliability.

How LTPO Enables Variable Refresh Rate and Lower Power Consumption

To further optimize power efficiency, the display industry introduced LTPO (Low-Temperature Polycrystalline Oxide) technology.

LTPO combines LTPS and IGZO TFTs on a single backplane, allowing the display to dynamically adjust its refresh rate based on content:

-

Static content: refresh rate can drop to 1–10 Hz

-

Dynamic content: refresh rate increases to 60 Hz, 120 Hz, or higher

This adaptive refresh capability significantly reduces power consumption without compromising user experience. Since its commercial introduction in 2018, LTPO has become a signature technology for premium AMOLED displays, especially in smartwatches and flagship devices.

How Is OLED Burn-In Addressed?

OLED “burn-in” is caused by uneven aging of organic emissive materials. To mitigate this issue, several advanced color and structural solutions have been developed.

WOLED (White OLED + Color Filter)

-

Uses a uniform white emissive layer

-

RGB colors are generated through color filters

-

Ensures consistent aging across sub-pixels

-

Widely adopted in large-size OLED displays

QD-CC (Quantum Dot Color Conversion)

-

Based on a blue OLED light source

-

Quantum dot materials convert part of the light into red and green

-

Delivers higher color purity and improved efficiency

-

Balances color performance with long-term reliability

How Tandem OLED Structures Improve Brightness and Lifetime

For high-brightness and long-lifetime applications, tandem OLED (stacked OLED) structures are increasingly used.

By stacking multiple OLED emissive units connected through a Charge Generation Layer (CGL), tandem OLED offer:

-

Higher brightness at the same driving current

-

Reduced stress on individual emissive layers

-

Extended overall device lifetime

This architecture has enabled the mass production of advanced solutions such as WOLED and QD-OLED panels.

Is MicroLED the Ultimate Competitor to AMOLED?

Looking ahead, MicroLED is considered a strong candidate for next-generation display technology.

Key advantages include:

-

Inorganic materials (e.g., GaN) with extremely long lifespan

-

Exceptional brightness and energy efficiency

-

Self-emissive structure without backlight or color filters

-

Strong potential for AR/VR and outdoor applications

However, challenges such as mass transfer accuracy, yield control, and cost reduction remain significant. In the foreseeable future, AMOLED will continue to dominate the high-end small-to-medium display market.

The Future of Display Technology

Whether through continuous LCD optimization or rapid advancements in AMOLED and MicroLED, the display industry is consistently moving toward:

-

Higher visual performance

-

Lower power consumption

-

Longer operational lifetime

-

Greater customization flexibility

These developments support a wide range of custom display modules, wearable devices, and emerging application scenarios.

AMOLED Display Solutions for High-End Applications

As an AMOLED display supplier, our solutions are widely adopted in smartwatches, premium wearable products, and innovative display-enabled devices, helping customers enhance visual quality and user experience.

From technology selection to custom engineering, we are committed to transforming advanced display technologies into reliable, scalable, and market-ready solutions.

Website Layout & Image Placement Recommendations

(For Product Pages & Technology Landing Pages)

Section 1: Hero Banner

Image:

-

High-resolution AMOLED product image (smartwatch / wearable display)

Text Overlay: -

“AMOLED Display Technology – Designed for Precision and Performance”

Section 2: AMOLED Core Architecture

Image:

-

Layered structure diagram

-

Cover glass

-

OLED emissive layer

-

TFT backplane

-

TFE encapsulation

-

Tip:

Use a simple exploded-view illustration with callout labels for engineers and OEM buyers.

Section 3: Backplane Technology Comparison

Image:

-

LTPS vs Oxide TFT comparison graphic

-

Optional table showing mobility, leakage current, and application use cases

Section 4: LTPO & Power Optimization

Image:

-

Variable refresh rate timeline (1 Hz → 120 Hz)

-

Power consumption comparison chart

Section 5: Burn-In Solutions & OLED Structures

Image:

-

WOLED vs QD-CC color generation diagram

-

Tandem OLED stacked structure illustration

Section 6: Future Display Technologies

Image:

-

Concept visuals for MicroLED, AR/VR displays

-

Clean, futuristic design style

Section 7: Application Showcase

Image:

-

Smartwatch

-

Wearable electronics

-

Customized AMOLED modules

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

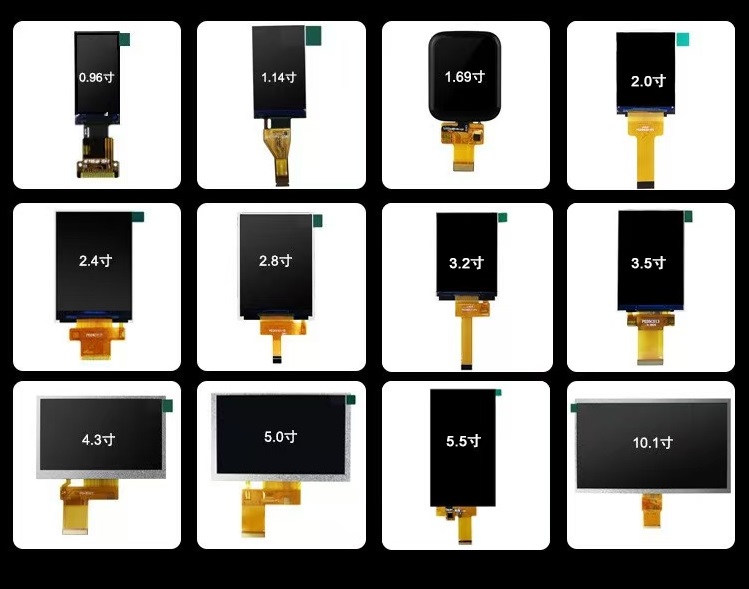

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch