News

Touchscreen technology plays an important role in digital manufacturing

touchscreen technology plays an important role in digital manufacturing

Touch screen technology plays an important role in digital manufacturing. Here are several aspects of how it contributes to digital manufacturing:

1. Human-computer interaction interface: As one of the human-computer interaction interfaces, touchscreen can provide intuitive, flexible and convenient operation methods. In digital manufacturing, operators can interact with equipment, robots and production lines through touch screens to control and monitor the production process. The friendliness and intuitiveness of the touch screen interface make it easier for operators to understand and master the use of production equipment, improving operating efficiency and production quality.

2. Real-time monitoring and data analysis: The touchscreen can be used for real-time monitoring and data analysis, helping operators understand production conditions in real time by displaying production data, process parameters, equipment status and other information. At the same time, the touch screen interface can also provide visual data analysis and reporting functions to help managers make decisions and optimize the production process.

3. Flexible production scheduling: The touchscreen can be used for flexible production scheduling. Through simple operations on the interactive interface, the equipment ratio, process parameters and process sequence of the production line can be adjusted to achieve rapid conversion and flexible scheduling of the production line. This kind of flexible production scheduling can adapt to product changes and market demands in a short period of time, improving the flexibility and production efficiency of the production line.

4. Fault diagnosis and maintenance: The touchscreen can also be used for fault diagnosis and equipment maintenance. When a fault or abnormality occurs in the equipment, through the fault alarm and diagnosis functions on the touch screen interface, operators can quickly locate and solve the problem, reducing downtime of the production line. In addition, the touch screen interface can also provide maintenance manuals, operating instructions and equipment maintenance tips to help operators perform equipment maintenance and upkeep.

Touch screen technology plays an important role in digital manufacturing. The following are several aspects of touch screen in digital manufacturing:

1. Visual operation and control: Touch screen technology makes the operation interface more intuitive and visual. It provides a simple and easy-to-use user interface, allowing operators to easily control and operate equipment, robots, automation systems, etc. Through the touch screen, operators can start and stop equipment, adjust parameters, monitor production and other operations, thereby improving the flexibility and operating efficiency of the production line.

2. Data collection and monitoring: The touch screen is connected to sensors and data collection systems, and can obtain various data in the production process in real time, such as temperature, pressure, humidity, etc. Operators can monitor and analyze these data through the touch screen and make real-time adjustments and optimizations to the production process. The touch screen can present real-time data charts, alarm information, etc., helping operators find and solve problems in a timely manner.

3. Parameter adjustment and optimization: In digital manufacturing, parameter adjustment and optimization during the production process are very important. The touch screen interface provides convenient operation and adjustment functions. Operators can set and modify production line parameters through the touch screen, and adjust equipment operating modes, production specifications, etc. in real time to meet different product needs and production goals.

4. Fault diagnosis and maintenance: When equipment failure or abnormal conditions occur, the touch screen interface can provide fault diagnosis and alarm information. Operators can obtain fault codes, fault solutions and maintenance instructions through the touch screen, and guide repair and maintenance personnel to carry out corresponding troubleshooting and repair work.

5. Production data analysis and optimization: The touch screen can collect, store and analyze data in the production process, and provide data reports, trend analysis and prediction functions. Through the touch screen interface, operators can analyze production data. Production touch screen technology plays an important role in digital manufacturing. Here are a few key aspects of how touch screens can power digital manufacturing:

6. Human-machine interface: As an intuitive and highly interactive human-machine interface, the touch screen can provide convenient operation and control methods. In digital manufacturing, operators can monitor and control equipment and production processes in real time through touch screens, and perform parameter settings and adjustments to achieve efficient production management and process control.

7. Data visualization: The touch screen can be used for data display and visualization, and the data in the production process can be displayed on the screen in the form of charts, images or animations. Operators can intuitively understand key indicators such as production status, product quality and equipment performance through the touch screen, so as to make decisions and optimize.

8. Production monitoring and traceability: Through the touch screen, operators can monitor the operating status of the production line, product processing and quality parameters in real time. The touch screen can also record and trace production data, such as production time, production quantity and production batch, to support quality management and traceability needs.

9. Equipment networking and remote control: The touch screen can be connected to the remote monitoring and control system of equipment and production lines to achieve remote equipment management and control. Through the touch screen, operators can remotely access equipment data, perform remote operations and adjust parameters, thereby achieving the goals of remote monitoring and collaborative production.

10. Smart factory integration: As part of smart factory integration, touch screens can be connected and integrated with other production management systems, industrial automation equipment and Internet of Things devices. Through the touch screen, operators can interact with other systems and equipment for data interaction, instruction transmission, and collaborative operations to achieve collaboration, automation, and intelligence in digital manufacturing.

If you have touchscreen technology for digital manufacturing, you can leave a message to our DINGTOUCH technical team for communication.

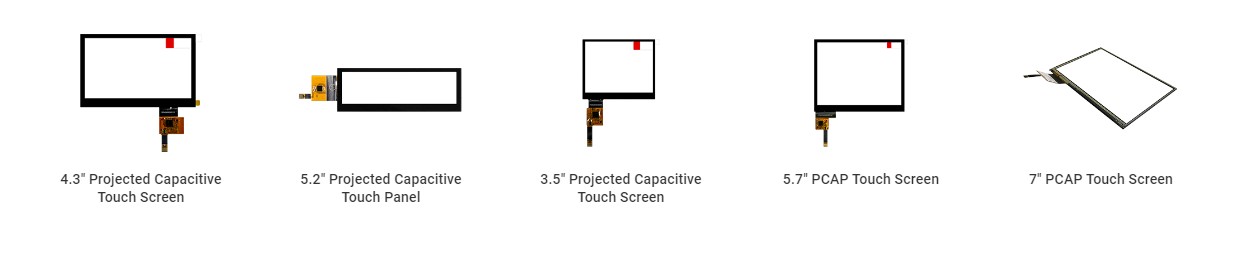

DINGTOUCH is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTOUCH is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touch screen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs. Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch